Custom stainless steel filter water Manufacturers and suppliers

Custom Stainless Steel Water Filters: Your Guide to Quality and Efficiency

As industries evolve, the demand for high-quality filtration solutions becomes crucial. At Lvyuan, we specialize in custom stainless steel water filters tailored to meet diverse applications across various sectors. Our expertise not only lies in design but also in manufacturing high-performing sintered filters and filter housings. Here’s a comprehensive guide to why our stainless steel filter water solutions are essential for your business.

Stainless steel filters have become the gold standard in filtration technology. The benefits include:

- Durability and Longevity: Made to withstand extreme conditions, these filters ensure long-term use.

- Corrosion Resistance: An essential feature for applications involving water and other corrosive media.

- Hygienic Properties: Vital for industries such as food and beverage, pharmaceuticals, where cleanliness is crucial.

- Environmental Sustainability: Stainless steel filters are often reusable and fully recyclable.

At Lvyuan, our custom stainless steel filters cater to these strengths, ensuring you're equipped with the best in the market.

Key Features of Lvyuan Stainless Steel Filters

1. Customized Solutions: Our commitment to customization ensures that we deliver filters meeting specific industrial requirements. From pore size to dimensions, every aspect is tailored for optimal performance.

2. Advanced Manufacturing: Leveraging state-of-the-art technology, our manufacturing processes ensure precision, consistency, and superior product standards.

3. Cost-Efficiency: While initially more expensive than other materials, the durability and reusability of stainless steel filters make them a cost-effective solution over time.

4. Compliance and Safety: Our filters meet global standards and regulations, ensuring they are safe for use in any environment or application.

Applications of Stainless Steel Filters

- Water Treatment Facilities: Provide efficient and reliable filtration, ensuring clean and safe water supply.

- Pharmaceutical Industry: Maintain sterile conditions, crucial for the safe production of pharmaceuticals.

- Oil and Gas Industries: Manage complex filtration processes effectively, dealing with challenging liquids and operations.

- Food and Beverage Production: Ensure the highest standard of sanitation in the filtration process.

Frequently Asked Questions (FAQ)

Q1: What sizes are available in Lvyuan's stainless steel filters?

A: We offer a broad range of sizes, but we can also custom-design filters to meet specific requirements.

Q2: How long does a stainless steel filter last?

A: With proper maintenance, our stainless steel filters can last several years, making them a practical investment.

Q3: Are stainless steel filters environmentally friendly?

A: Yes, they are fully recyclable and contribute significantly less waste compared to disposable filters.

Q4: Can Lvyuan assist with large order quantities?

A: Absolutely. We are fully equipped to handle large-scale manufacturing projects efficiently.

Conclusion

Choosing the right filter is critical to ensuring quality and efficiency in your operations. At Lvyuan, our custom stainless steel water filters are a testament to our commitment to excellence. With us, you gain a partner that understands your challenges and provides tailor-made filtration solutions that meet your specific needs.

Ready to enhance your filtration system with quality stainless steel filters? Contact Lvyuan today and discover why we're the go-to choice for industries worldwide. Embrace the future of filtration with confidence and reliability.

By incorporating your unique requirements and upholding rigorous standards, Lvyuan guarantees outstanding performance in every stainless steel filter we manufacture. Discover the Lvyuan difference and elevate your business's efficiency and sustainability.

The Ultimate Guide to Water Filter Screen Mesh: Everything You Need to Know

Discover the 50 Micron Stainless Steel Filter by Lvyuan

Custom sinter filter Manufacturers and suppliers

The Guide to Stainless Steel Cartridge Filter Housing

Sintered Metal Filters

What is a sintered metal filters?

A sintered metal filter is a porous material produced by compacting and heating metal particles to create a solid structure with interconnected pores. It is commonly used for filtration in various industries.

Porous Plastic Filter

How do I clean and maintain sintered plastic porous filters?

Sintered plastic porous filters can be cleaned using various methods, such as backwashing, ultrasonic cleaning, chemical cleaning, and steam sterilization, depending on the type of contaminants and the filter's compatibility with cleaning agents. Regular maintenance, such as inspection and replacement of filters, is essential to ensuring optimal performance.

Sintered mesh filters

Can sintered mesh filters be customized for specific requirements?

Yes, sintered mesh filters are highly customizable. They can be tailored based on factors such as filtration rating, material composition (e.g., stainless steel, monel), dimensions, and shape to meet the unique needs of different applications.

Sintered Titanium Filters

What Applications Are Sintered Titanium Filters Suitable For?

Sintered titanium filters are versatile and find applications in water treatment, gas diffusion, chemical experiments, and pharmaceutical processes due to their temperature resistance and corrosion resilience.

For company

Product advantages

• Quality Assurance:

We prioritizes quality as a cornerstone of its operations. We adhere to rigorous quality control standards throughout the manufacturing process to ensure that our products meet the highest industry standards.

• Innovative Technology:We leverage cutting-edge technologies in the design and production of our products. By staying at the forefront of technological advancements, we provide our customers with innovative solutions that meet their evolving needs.

• Diverse Product Range:

We offer a comprehensive and diverse range of products, catering to various industries and applications. Our extensive product portfolio allows customers to find solutions tailored to their specific requirements.

• Customization Capabilities:

Recognizing the unique needs of our customers, we provide customizable options for our products. This ensures that our clients receive tailored solutions that align with their individual preferences and applications.

• Competitive Pricing:

We are committed to offering competitive prices without compromising on quality. Our cost-effective solutions enable customers to access high-quality products at reasonable and competitive market rates.

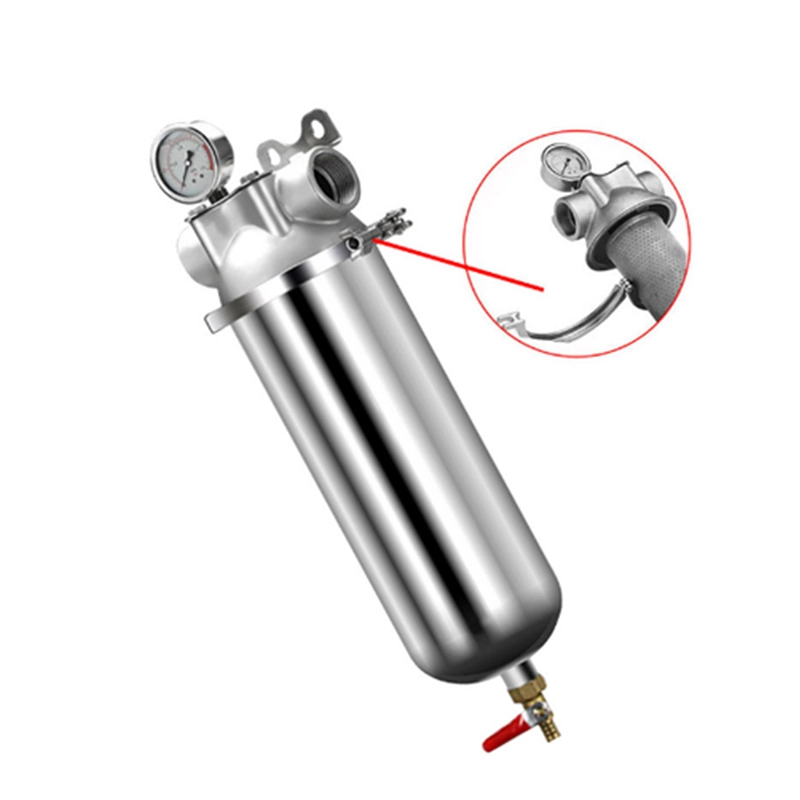

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

Stainless Steel Duplex filter housing

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions