How to Choose a Suitable Sintered Metal Filter for Your Needs | Lvyuan

- Understanding Sintered Metal Filters: A Foundation for Efficiency

- Why Choose a Sintered Metal Filter?

- Key Considerations When Selecting a Sintered Metal Filter

- Industries Benefiting from Sintered Metal Filters

- Innovations and Certifications: Why Trust Lvyuan?

- Conclusion: Making Informed Choices with Lvyuan

- FAQs: Addressing Common Queries

- 1. What is the lifespan of a sintered metal filter?

- 2. Can sintered metal filters be customized?

- 3. How do I determine the right filtration grade?

- 4. Are sintered metal filters environmentally friendly?

Setting the Stage for Optimal Filtration

In today’s complex industrial landscape, ensuring the quality and efficiency of your filtration process is paramount. Understanding how to choose a suitable sintered metal filter, with expertise from industry leaders like Lvyuan, can make a significant difference in your operations. This comprehensive guide helps you navigate the essentials of selecting the right filter for versatile applications.

Understanding Sintered Metal Filters: A Foundation for Efficiency

Sintered metal filters have revolutionized the filtration industry with their durability, versatility, and efficiency. These filters are made by compressing and sintering metal powders, resulting in a porous structure that offers high mechanical strength and thermal stability. Recognizing the varied applications, Lvyuan specializes in producing a wide range of sintered metal filters tailored for diverse industries, ensuring high-performance filtration and separation processes.

Why Choose a Sintered Metal Filter?

Choosing sintered metal filters comes with several advantages, including superior filtration accuracy, excellent corrosion resistance, and extended lifespan. They serve critical roles in sectors like food and beverage, petrochemical, and biotechnology. For businesses seeking reliable and robust filtration solutions, understanding how to choose a suitable sintered metal filter is crucial. Lvyuan’s extensive range ensures that customers have access to optimized solutions for their specific needs.

Key Considerations When Selecting a Sintered Metal Filter

1. Material Compatibility and Corrosion Resistance

A primary consideration is the filter’s material compatibility with the substances being processed. Sintered metal filters from Lvyuan are crafted with high-grade materials such as stainless steel, offering excellent corrosion resistance, vital for industries handling aggressive substances.

2. Filtration Efficiency and Particle Retention

The filter's porosity plays a central role in determining its efficiency. Selecting a suitable sintered metal filter requires an understanding of the desired filtration grade, critical for achieving the required purity levels in liquid or air filtration applications.

3. Mechanical Strength and Durability

Sintered metal filters must withstand operational pressures and temperatures. Lvyuan's products are engineered for exceptional mechanical strength, ensuring they perform reliably under demanding conditions, reducing downtime and maintenance costs.

4. Customizability and Size Requirements

Each application may have unique requirements. Lvyuan's capability in providing OEM and ODM services enables the production of customized sintered metal filters tailored to specific operational needs, ensuring optimal fit and performance.

Industries Benefiting from Sintered Metal Filters

Sintered metal filters find application across various industries due to their robustness and adaptability. From the biopharmaceutical industry, where cleanliness and sterility are paramount, to the petrochemical and electronic sectors, these filters provide reliable solutions for filtration, separation, and purification challenges. Lvyuan has successfully catered to over 1,000 clients globally, providing tailored solutions that enhance operational efficiency and cost-effectiveness.

Innovations and Certifications: Why Trust Lvyuan?

Founded in 2009, Guangzhou Lvyuan Water Purification Equipment Co., Ltd. has established itself as a pioneer in filtration technology. Our continuous investment in R&D, coupled with certifications like CE, ROHS, and SGS, underscores our commitment to quality and innovation. By choosing Lvyuan, customers gain access to a trusted partner adept at providing cutting-edge filtration solutions backed by industry-recognized standards.

Conclusion: Making Informed Choices with Lvyuan

In conclusion, understanding how to choose a suitable sintered metal filter is pivotal to ensuring efficient and reliable filtration processes. By considering factors such as material compatibility, filtration efficiency, and mechanical durability, customers can make informed decisions that match their specific needs. Lvyuan stands at the forefront of the filtration industry, dedicated to providing innovative solutions that empower businesses to thrive. Trust us to deliver unparalleled quality and expertise for all your filtration needs.

FAQs: Addressing Common Queries

1. What is the lifespan of a sintered metal filter?

The lifespan varies based on usage, maintenance, and operating conditions. However, sintered metal filters are renowned for their durability, often lasting longer than traditional filters.

2. Can sintered metal filters be customized?

Yes, Lvyuan offers extensive customization services, enabling filters to be tailored to specific industrial requirements and applications.

3. How do I determine the right filtration grade?

Consider the specific particle size you need to filter. Consulting with experts, like those at Lvyuan, can provide guidance tailored to your application needs.

4. Are sintered metal filters environmentally friendly?

Yes, they are reusable and can be cleaned, reducing waste compared to disposable filters, aligning with sustainable practices.

By following this guide and considering Lvyuan’s expertise, selecting the right sintered metal filter for your application becomes an informed and straightforward process.

Tips for Wholesale Sintered Metal Filter Manufacturer in US

The Ultimate Guide to Water Bag Filter Housing: Everything You Need to Know

The Application of Sintered Metal Filters in the Pharmaceutical Industry | Lvyuan

The Ultimate Guide to Water Filter Screen Mesh: Everything You Need to Know

Sintered Metal Filters

What are the advantages of sintered metal filters?

Sintered metal filters offer high strength, durability, and resistance to temperature and corrosion. They provide precise filtration, are reusable, and suitable for diverse applications.

For company

How is production capacity?

• Sintered metal filters: 10,000 sets per month.

• Filter housings: 5000 sets/month.

• PE filters: 100000 pcs/month.

• And our production capacity is growing.

Porous Plastic Filter

Can sintered porous filter discs withstand high temperatures?

Yes, depending on the material selected (e.g., stainless steel or nickel alloys), sintered porous filter discs can withstand high temperatures, making them suitable for applications involving elevated temperatures.

For customization

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Metal mesh filters

What types of contaminants can sintered wire mesh filter?

Sintered wire mesh can filter a wide range of contaminants, including particles, solids, and impurities from liquids and gases. The filtration efficiency depends on factors such as pore size and material selection.

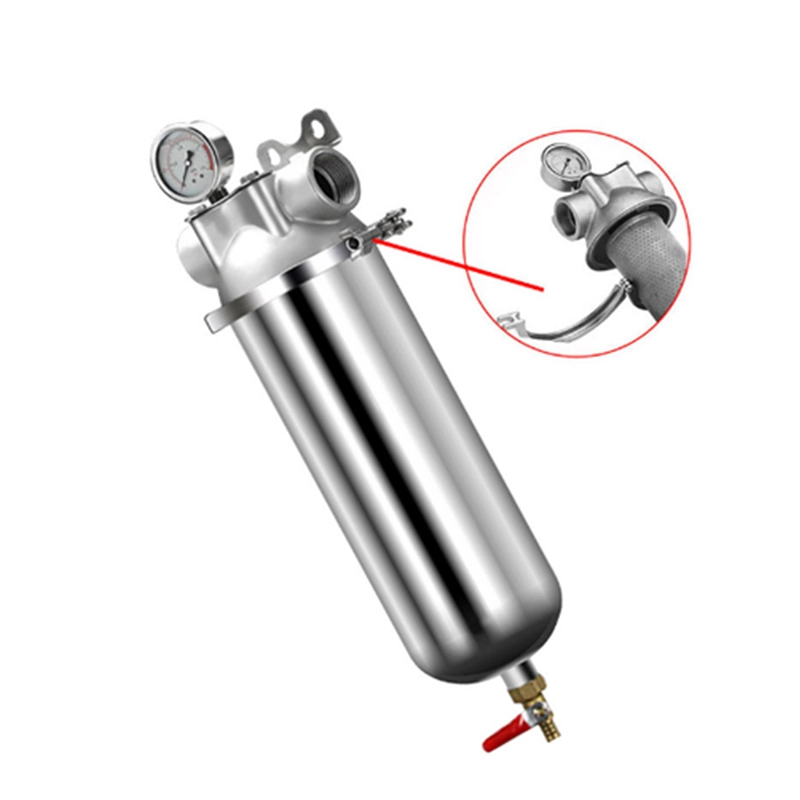

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions