Ознакомьтесь с трубками из спеченного металла от Lvyuan: передовые решения для фильтрации.

Ознакомьтесь с трубками из спеченного металла от Lvyuan: передовые решения для фильтрации.

Добро пожаловать в Lvyuan, профессиональное и надежное предприятие, занимающееся технологическими инновациями, исследованиями и разработками, а также производством передовых решений в области фильтрации с 2009 года. В основе наших передовых разработок лежат высокоэффективные трубки из спеченного металла, разработанные для обеспечения непревзойденной фильтрации, разделения и очистки в самых разных промышленных областях. Опираясь на традиции качества, инноваций и доверия клиентов, Lvyuan использует более чем десятилетний опыт для поставки надежных и эффективных фильтрующих продуктов более чем 1000 клиентам в 85 странах мира.

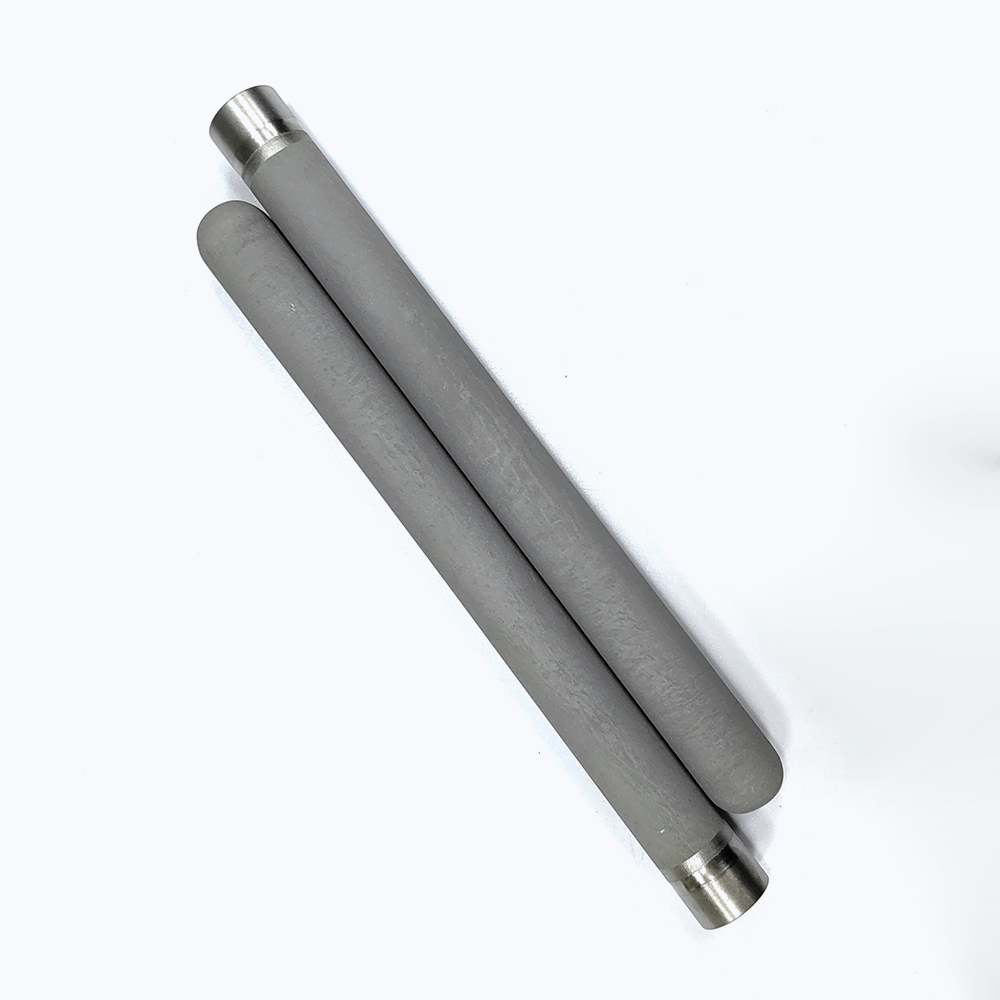

Что такое спеченные металлические трубы?

Спеченные металлические трубки представляют собой высокопрочные пористые фильтрующие элементы, изготовленные из металлических порошков (например, нержавеющей стали) методом спекания. Этот процесс уплотняет порошок в жесткую монолитную структуру с точно контролируемыми размерами пор и высокой пористостью. Эти трубки разработаны для работы в сложных условиях, обеспечивая исключительную механическую прочность, превосходную коррозионную стойкость и устойчивость к высоким температурам, что делает их идеальными для сложных задач фильтрации, где обычные фильтры не справляются.

Основные характеристики и преимущества спеченных металлических труб Lvyuan

Спеченные металлические трубы компании Lvyuan отличаются превосходным дизайном и качеством изготовления:

- Высокоточная фильтрация: равномерное распределение пор обеспечивает стабильное и высокоэффективное удаление загрязнений.

- Высокая износостойкость: Обладает исключительной прочностью, устойчив к деформации и повреждениям даже при высоких перепадах давления.

- Химическая и термостойкость: подходит для работы с агрессивными химическими веществами и при экстремальных температурах, при которых другие материалы разрушаются.

- Длительный срок службы: легко чистится и промывается обратным потоком воды, что продлевает срок службы и снижает затраты на замену.

- Возможности индивидуальной настройки: Доступны различные материалы, размеры и параметры пор, а также услуги OEM и ODM для удовлетворения конкретных требований к применению.

Разнообразные применения в разных отраслях промышленности

Универсальность и высокие эксплуатационные характеристики спеченных металлических труб Lvyuan делают их незаменимыми во многих ответственных отраслях промышленности:

- Продукты питания и напитки: обеспечение чистоты и прозрачности продукции.

- Нефтехимическая и химическая промышленность: работа с коррозионно-активными жидкостями и газами, регенерация катализаторов.

- Биофармацевтика и медицина: стерилизующая фильтрация, удаление мелких частиц в чувствительных процессах.

- Машиностроение: защита чувствительного оборудования от загрязнения твердыми частицами.

- Электроника и электротехника: Обеспечение фильтрации чистого воздуха и жидкостей для чувствительных компонентов.Наши решения пользуются доверием во всем мире, обеспечивая необходимую фильтрацию, разделение и очистку, повышая эффективность и безопасность.

Почему стоит выбрать Lvyuan для ваших потребностей в спеченных металлических трубах?

Выбирая Lvyuan, вы сотрудничаете с сертифицированным лидером в области фильтрационных технологий. Мы гордимся наличием сертификатов CE, ROHS, SGS и других соответствующих документов, что подчеркивает нашу приверженность международным стандартам качества. Помимо нашего обширного ассортимента продукции, который включает в себя...Корпуса фильтров из нержавеющей сталиВ сфере производства и выпуска полиэтиленовых фильтров мы уделяем особое внимание исследованиям и разработкам, а также предоставляем услуги OEM и ODM, ориентированные на клиента, что гарантирует индивидуальные решения для ваших уникальных задач. Оцените преимущества Lvyuan – надежная продукция, экспертная поддержка и глобальное присутствие, направленное на решение самых сложных задач фильтрации.

Дисплей из спеченной металлической трубки

- Стерильная фильтрация

Фильтры из спеченного металласпособны осуществлять стерильную фильтрацию, что имеет решающее значение при производстве фармацевтических ингредиентов и в других областях, где важно поддержание стерильной среды.

- Совершенство производства

Наши производственные процессы соответствуют самым высоким отраслевым стандартам, гарантируя выпуск продукции высочайшего качества.нержавеющая сталь спеченнаяФильтры славятся своей прочностью, эффективностью и долговечностью.

- Гигиенический дизайн

Фильтры из спеченного металла разработаны из материалов, которые соответствуют стандартам гигиены для пищевых продуктов. Их легко чистить и дезинфицировать, что предотвращает бактериальное загрязнение и обеспечивает соответствие отраслевым нормам.

- Эффективная фильтрация

Гофрированная конструкция значительно увеличивает площадь поверхности, доступную для фильтрации.

Как сделатьфильтр-картридж из нержавеющей сталижилье работает?

Фильтр из нержавеющей сталиКорпуса работают по принципу пропускания технологической жидкости через фильтрующий элемент, где загрязняющие вещества задерживаются на фильтрующем материале, позволяя чистой жидкости проходить через корпус и выходить из него.

Как мы можем гарантировать качество?

Перед началом массового производства всегда снимайте предварительный образец.

Наше современное испытательное оборудование и строгое соблюдение стандартов контроля качества гарантируют, что наши корпуса фильтров и фильтрующие элементы соответствуют стандарту ISO 9001.

Когда был основан Льюиуан?

Компания «Люйюань» была основана 12 октября 2009 года.

Как чистить и обслуживать фильтр из металлокерамической сетки?

Фильтры из спеченной сетки обычно легко очищаются. Их можно очищать с помощью таких методов, как обратная промывка, ультразвуковая очистка или химическая очистка. Регулярное обслуживание помогает продлить срок службы фильтра и поддерживать оптимальную производительность.

Корпус многокартриджного фильтра из нержавеющей стали

Корпус многокартриджного фильтра из нержавеющей стали

Фильтрующий картридж из нержавеющей стали с гофрированными стенками

Фильтрующий картридж из нержавеющей стали с гофрированными стенками

производители корпусов фильтров из нержавеющей стали

производители корпусов фильтров из нержавеющей стали© 2024 Все права защищены. |Политика конфиденциальности•Условия и положения