OEM/ODM sintered metal candle filter Manufacturers and Suppliers

- High-Quality Sintered Metal Candle Filters: OEM/ODM Solutions from Lvyuan

- Understanding Sintered Metal Candle Filters

- The Lvyuan Advantage: OEM/ODM Sintered Metal Candle Filter Manufacturing

- Superior Quality and Certifications

- Diverse Applications of Sintered Metal Candle Filters

- Food and Beverage Industry:

- Machinery Manufacturing:

- Petrochemical Industry:

- Biopharmaceutical and Medical Industries:

- Electronic and Electrical Industries:

- Choosing the Right Sintered Metal Candle Filter: Material Selection

- Lvyuan: Your Trusted Partner for OEM/ODM Sintered Metal Candle Filters

- Contact Lvyuan Today

- Frequently Asked Questions (FAQ)

- Conclusion

High-Quality Sintered Metal Candle Filters: OEM/ODM Solutions from Lvyuan

Understanding Sintered Metal Candle Filters

Sintered metal candle filters are a crucial component in numerous industrial applications requiring high-efficiency filtration. These filters, manufactured using a process of powder metallurgy, offer unparalleled durability, precision, and chemical resistance. Their unique construction, with interconnected pores, allows for effective removal of particles across a wide range of sizes, ensuring superior product purity and system longevity. Lvyuan's sintered metal candle filters are engineered to meet the most demanding specifications, providing reliable performance across diverse industries.

The Lvyuan Advantage: OEM/ODM Sintered Metal Candle Filter Manufacturing

Lvyuan, a prominent name in the filtration industry, offers comprehensive OEM/ODM services for sintered metal candle filters. This means we collaborate closely with clients to design and manufacture customized filters that perfectly align with their specific requirements. Our experienced engineering team utilizes advanced technology and rigorous quality control measures throughout the entire manufacturing process, guaranteeing superior product quality and consistent performance. Partnering with Lvyuan translates to cost-effectiveness, efficient production timelines, and unparalleled customer support.

Superior Quality and Certifications

Quality is paramount at Lvyuan. Our commitment to excellence is reflected in our adherence to stringent international standards and certifications. Our sintered metal candle filters carry the CE, ROHS, and SGS certifications, ensuring compliance with global safety and environmental regulations. These certifications provide our clients with the assurance that they are investing in high-quality, reliable filtration solutions that meet and exceed industry benchmarks. This commitment to quality underscores our dedication to delivering exceptional products and services to our valued customers worldwide.

Diverse Applications of Sintered Metal Candle Filters

Lvyuan’s sintered metal candle filters find extensive application across a variety of sectors:

Food and Beverage Industry:

In the food and beverage industry, maintaining the highest standards of hygiene and product purity is crucial. Our sintered metal candle filters effectively remove contaminants, ensuring the safety and quality of food and beverages. They are resistant to corrosion and can withstand harsh cleaning agents, ensuring long-term functionality and hygiene.

Machinery Manufacturing:

Lvyuan's filters play a vital role in protecting sensitive machinery components from damage caused by contaminants in lubricants and hydraulic fluids. The superior filtration provided by our filters extends the lifespan of machinery and reduces costly downtime.

Petrochemical Industry:

The petrochemical industry often utilizes Lvyuan sintered metal candle filters for processes requiring extremely high levels of filtration accuracy. These filters are engineered to withstand high temperatures and pressures, ensuring reliable performance even in demanding operational environments.

Biopharmaceutical and Medical Industries:

Purity and sterility are paramount in the biopharmaceutical and medical industries. Lvyuan's sintered metal candle filters are ideal for applications requiring stringent filtration standards, ensuring the safety and efficacy of pharmaceuticals and medical devices. Our filters are designed to minimize the risk of contamination and maintain the integrity of sensitive products.

Electronic and Electrical Industries:

In the electronics and electrical sectors, Lvyuan's filters contribute to ensuring the quality and performance of electronic components by removing impurities from cooling fluids and other liquids. The superior filtration provided extends the lifespan of electronic components and reduces potential failures.

Choosing the Right Sintered Metal Candle Filter: Material Selection

Lvyuan provides a wide array of sintered metal candle filter materials to meet your specific application needs. These materials are carefully selected for their unique properties, ensuring optimal performance in various environments:

* Stainless Steel: Offers exceptional corrosion resistance, high-temperature tolerance, and durability, making it ideal for demanding applications.

* Bronze: Provides excellent corrosion resistance and thermal conductivity, suitable for specific industrial applications.

* Monel: A nickel-copper alloy, Monel offers superior resistance to corrosion in harsh environments, ideal for chemical processing.

* Other Alloys: Lvyuan can also customize filters using other specialized alloys to meet unique application requirements, ensuring optimal performance and longevity.

The selection of the appropriate material depends on factors such as the nature of the fluid being filtered, the operating temperature and pressure, and the specific contaminant removal requirements. Our expert team can guide you through the selection process to ensure you choose the most suitable filter for your specific application.

Lvyuan: Your Trusted Partner for OEM/ODM Sintered Metal Candle Filters

For over a decade, Lvyuan has been a trusted name in the manufacturing and supply of high-quality sintered metal candle filters. Our commitment to excellence, coupled with our extensive experience in OEM/ODM services, positions us as a leading provider of filtration solutions worldwide. Our focus on innovation, quality control, and customer satisfaction ensures that we consistently exceed expectations.

Contact Lvyuan Today

Are you looking for a reliable partner for your sintered metal candle filter needs? Contact Lvyuan today to discuss your project requirements. Our experienced team is ready to assist you in selecting the optimal filter solution, providing customized design, and ensuring prompt delivery of high-quality products. We are committed to building long-term partnerships with our clients, providing exceptional service and support throughout the entire process. Let Lvyuan help you achieve optimal filtration performance in your specific application.

Frequently Asked Questions (FAQ)

Q: What types of sintered metal candle filters does Lvyuan offer?

A: We offer a wide range of sintered metal candle filters in various materials (stainless steel, bronze, Monel, and others), porosities, and sizes to suit diverse applications.

Q: What are the benefits of using Lvyuan's OEM/ODM services?

A: Our OEM/ODM services offer customized filter solutions tailored to your exact specifications, ensuring optimal performance and cost-effectiveness. You get access to our expertise and experience in filter design and manufacturing.

Q: What certifications do Lvyuan's filters have?

A: Our sintered metal candle filters are certified to meet CE, ROHS, and SGS standards, guaranteeing quality and safety.

Q: What industries do Lvyuan's filters serve?

A: Our filters are widely used in food and beverage, machinery manufacturing, petrochemical, biopharmaceutical, medical, and electronic industries.

Q: What is the lead time for OEM/ODM orders?

A: Lead times vary depending on the order size and complexity. Please contact us for an accurate estimate.

Q: How can I contact Lvyuan for a quote?

A: You can contact us through our website, email, or phone number provided on our contact page.

Q: What is the warranty on Lvyuan's filters?

A: We offer a warranty on our filters; the specific terms and conditions are available upon request.

Q: Does Lvyuan offer technical support?

A: Yes, we offer comprehensive technical support to assist you with filter selection, installation, and maintenance.

Q: What is the minimum order quantity (MOQ)?

A: Our MOQ varies depending on the specific product and customization. Please contact us for details.

Q: What payment methods does Lvyuan accept?

A: We accept various payment methods, including bank transfer, letter of credit, and others. Please contact us to discuss your preferred payment method.

Conclusion

Lvyuan is your reliable source for high-quality OEM/ODM sintered metal candle filters. With our commitment to quality, innovation, and customer satisfaction, we deliver superior filtration solutions tailored to your specific needs. Contact us today to experience the Lvyuan advantage.

Custom titanium rod filter Manufacturers and suppliers

What are the different types of Liquid Filtration?

The Ultimate Guide to Water Filter Screen Mesh: Everything You Need to Know

10 Micron Stainless Steel Filter Mesh: Innovative Filtration by Lvyuan

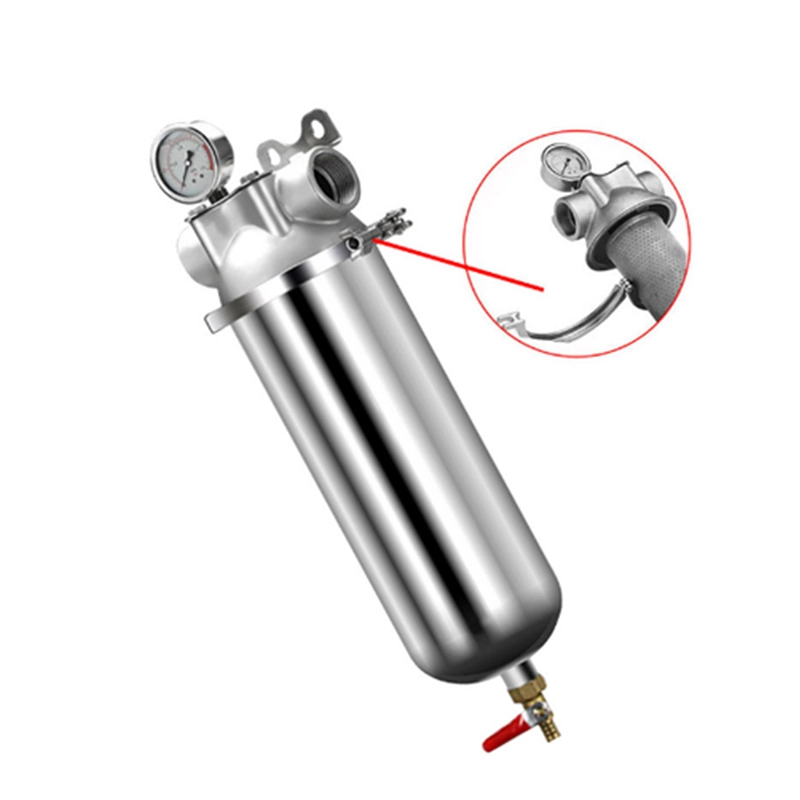

Stainless Steel Cartridge Filter Housing

What is a stainless steel cartridge filter housing?

The 304 or 316 stainless steel cartridge filter housing is a durable enclosure designed to hold filter cartridges or filter bags for the filtration of liquids or gases in industrial processes.

Sintered Metal Filter

What is an industrial sintered metal filter cartridge?

An industrial sintered filter cartridge is a filtration component made through a sintering process, combining metal powders to create a porous structure. These cartridges are designed for industrial applications to remove contaminants from liquids and gases.

What materials are commonly used in industrial-sintered metal filter cartridges?

Common materials include stainless steel (304, 316, and 316L), bronze, Inconel, Monel, titanium, and other alloys, depending on the specific requirements of the application.

What are the key advantages of using industrial-sintered metal filter cartridges?

Advantages include high filtration efficiency, durability, wide temperature resistance, chemical compatibility, customization options, high flow rates, ease of cleaning, and versatility across various industries.

Sintered Metal Filters

What is a sintered metal filters?

A sintered metal filter is a porous material produced by compacting and heating metal particles to create a solid structure with interconnected pores. It is commonly used for filtration in various industries.

For products

How are sintered metal filters cleaned?

Cleaning methods for sintered metal filters include backwashing, ultrasonic cleaning, and chemical cleaning. The method depends on the type of contaminants and the filter's specifications.

Sintered Titanium Filters

How Do Sintered Titanium Filters Work?

Sintered titanium filters function by allowing fluid or gas to pass through their porous structure, capturing particles and impurities, resulting in effective filtration.

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions