The Guide to 200 Micron Stainless Steel Filter Mesh for Effective Filtration

In the world of filtration, achieving optimal results often comes down to the quality and design of the filter media used. When it comes to efficient and reliable filtration, 200 micron stainless steel filter mesh emerges as a top choice for many industries. At Lvyuan, we take pride in delivering excellence through our innovative sintered filters and filter housings, including the highly effective 200 micron stainless steel filter mesh. we will delve into the various benefits, applications, and considerations related to this powerful filtration solution.

1. Understanding 200 Micron Stainless Steel Filter Mesh

200 micron stainless steel filter mesh is a fine, tightly woven mesh made from high-quality stainless steel wire. With a precise opening size of 200 microns, this filter media offers exceptional strength, durability, and excellent resistance to corrosion and temperature extremes. It provides efficient particle retention and uniform flow distribution, making it suitable for a wide range of filtration applications.

2. Key Benefits of 200 Micron Stainless Steel Filter Mesh

The use of 200 micron stainless steel filter mesh offers several key benefits for filtration systems. This includes superior mechanical strength, resistance to abrasion, high temperature tolerance, and the ability to withstand harsh chemicals and extreme operating conditions. Additionally, the precisely controlled pore size ensures reliable particle retention, resulting in enhanced filtration performance.

3. Applications of 200 Micron Stainless Steel Filter Mesh

The versatility of 200 micron stainless steel filter mesh makes it suitable for diverse applications across various industries. From pharmaceutical and food processing to chemical, petrochemical, and water treatment, this filter media proves instrumental in achieving efficient particle separation and purification.

4. Choosing the Right 200 Micron Stainless Steel Filter Mesh

When selecting 200 micron stainless steel filter mesh for a specific application, it's vital to consider factors such as flow rate, particle size distribution, operating temperatures, and chemical compatibility. Lvyuan's expertise in filter design and manufacturing ensures that our 200 micron stainless steel filter mesh meets the specific requirements of each application, guaranteeing optimal performance and longevity.

5. Lvyuan's Commitment to Excellence

As a leading industry filter manufacturer, Lvyuan is committed to delivering top-notch filtration solutions tailored to meet the unique needs of our customers. Our comprehensive range of sintered filters and filter housings, including 200 micron stainless steel filter mesh, reflects our dedication to quality, performance, and reliability in filtration.

6. Frequently Asked Questions

Q: What are the typical dimensions of 200 micron stainless steel filter mesh?

A: The standard dimensions of 200 micron stainless steel filter mesh include a thickness of 0.5mm, a width of 1m, and a length of 30m per roll. Custom dimensions can also be provided based on specific requirements.

Q: Can 200 micron stainless steel filter mesh be reused?

A: Yes, the durable and resilient nature of stainless steel allows 200 micron filter mesh to be cleaned and reused multiple times, making it a cost-effective filtration solution.

Q: Are there different grades of stainless steel used for 200 micron filter mesh?

A: Yes, various grades of stainless steel, such as 304 and 316, are commonly used for 200 micron filter mesh, each offering specific properties for different applications.

Q: What is the maximum operating temperature for 200 micron stainless steel filter mesh?

A: Depending on the grade of stainless steel used, 200 micron filter mesh can typically withstand operating temperatures ranging from 800°C to 1000°C, ensuring reliable performance in high-temperature environments.

Q: What industries can benefit from using 200 micron stainless steel filter mesh?

A: 200 micron stainless steel filter mesh caters to a wide range of industries, including pharmaceutical, food and beverage, chemical, petrochemical, water treatment, and more, where efficient and reliable filtration is crucial.

Conclusion:

In conclusion, the use of 200 micron stainless steel filter mesh offers unparalleled filtration performance, making it an indispensable component in various industrial filtration systems. At Lvyuan, we take pride in providing high-quality filtration solutions, including the superior 200 micron stainless steel filter mesh, to meet the diverse needs of our customers with excellence and reliability.

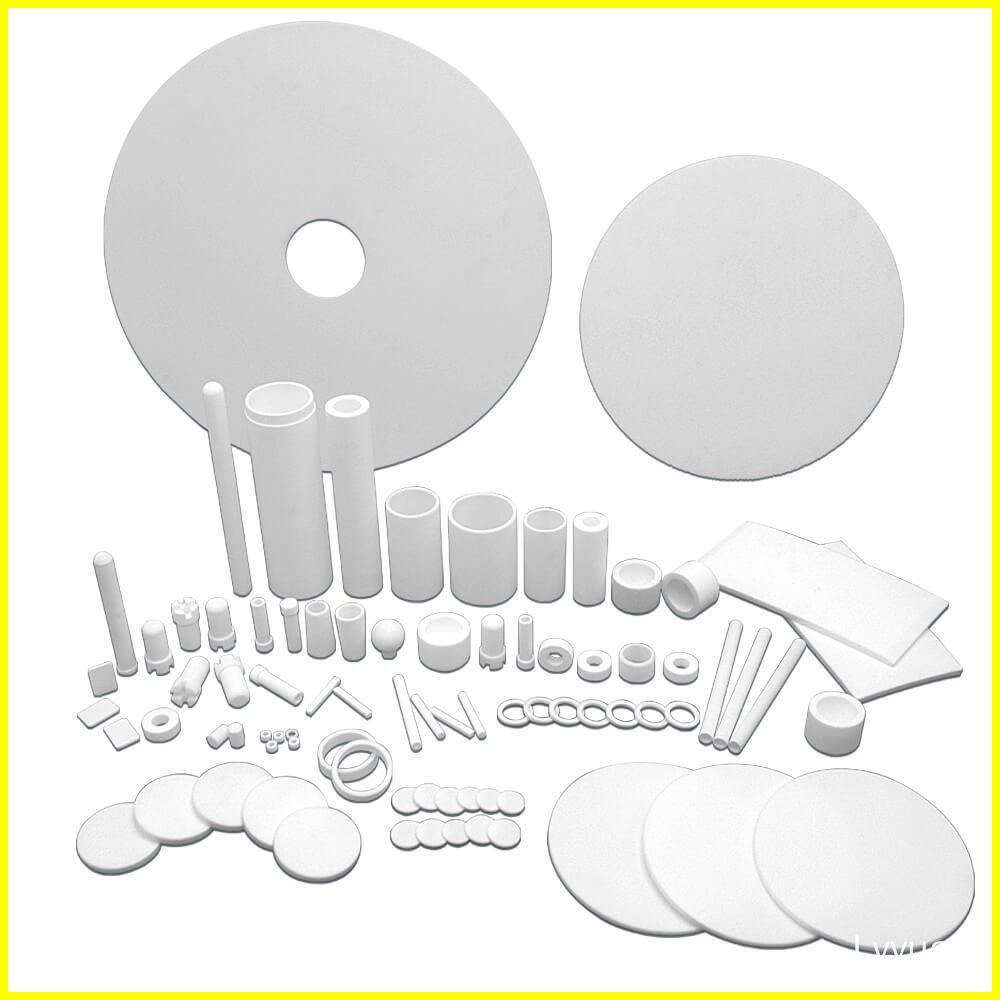

What is porous filter

Custom Steel house water filter Manufacturers and suppliers

Unlock Filter Excellence: OEM Sintered Metal Filter Makers - Lvyuan

How Are Sintered Metal Filters Made? - Lvyuan

Sintered Titanium Filters

Do Sintered Titanium Filters Offer High Flow Rates?

Yes, sintered titanium filters support high flow rates at low-pressure drops, optimizing efficiency and ensuring consistent filtration performance.

For customization

Do you supply OEM/ODM service?

Certainly, we have the capability to customize filter housing and filter elements according to your specific application. Our customization process adheres completely to your provided drawings, requirements, logo, and any other specifications you may have.

Sintered Powder Filters

Can sintered powder filters be used in corrosive environments?

Yes, sintered powder filters can be manufactured from corrosion-resistant materials, such as stainless steel or alloys like Inconel® and Monel®, making them suitable for use in corrosive environments.

What is a sintered powder filter?

A sintered powder filter is a porous filtration medium created by compacting and sintering metal powders. It is designed to provide efficient and precise filtration in various industrial applications.

Stainless Steel Pleated Filter Cartridges

Are these pleat cartridges corrosion-resistant?

Yes, the use of stainless steel (SS 304 or SS 316L) provides excellent corrosion resistance, making the cartridges suitable for applications where exposure to corrosive substances is a concern.

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions