What is porous filter

- Understanding Porous Filters: A Comprehensive Guide

- What is a Porous Filter?

- The Science Behind Porous Filters

- How Porous Filters Work

- Materials Used in Porous Filters

- Applications of Porous Filters

- Industrial Applications

- Healthcare and Biopharmaceutical Applications

- Benefits of Using Porous Filters

- Efficiency and Reliability

- Cost-Effectiveness

- Environmental Impact

- Innovations in Porous Filter Technology

- Advancements in Sintered Metal Filters

- OEM & ODM Services

- How to Choose the Right Porous Filter

- Understanding Industry Requirements

- Consulting with Filtration Experts

- Conclusion: The Future of Porous Filters

- FAQ Section

Understanding Porous Filters: A Comprehensive Guide

Introduction to Porous Filters

Porous filters play a critical role in a variety of industries, providing essential solutions for filtration, separation, and purification. At the forefront of this innovation is Guangzhou Lvyuan Water Purification Equipment Co., Ltd., a company dedicated to the research and development of advanced filtration technologies. But what exactly is a porous filter, and why are they indispensable across various sectors?

What is a Porous Filter?

Porous filters are specialized filtration devices made from materials that allow fluids or gases to pass through while capturing and retaining unwanted particles. These filters come in different forms, including sintered metal filters, PE filters, and stainless steel filter housings—all of which Lvyuan excels in manufacturing. Predominantly used in applications where precision and reliability are paramount, porous filters are designed to accommodate diverse industrial needs.

The Science Behind Porous Filters

How Porous Filters Work

The effectiveness of a porous filter lies in its composition. These filters are made of a matrix of tiny interconnected pores that allow for controlled diffusion of substances. The size of the pores determines which particles are retained and which are allowed to pass through. This unique feature is essential for industries requiring precise filtration, such as the biopharmaceutical and petrochemical sectors.

Materials Used in Porous Filters

Lvyuan manufactures porous filters using high-quality materials such as stainless steel and sintered metal. These materials are chosen for their durability, resistance to corrosion, and ability to withstand high temperatures, ensuring that the filters perform efficiently even in the most demanding environments.

Applications of Porous Filters

Industrial Applications

Porous filters are pivotal in numerous industries, including food and beverage, machinery manufacturing, medical and health, and electronics. In food and beverage production, they ensure the removal of impurities, enhancing product quality and safety. In machinery manufacturing, they aid in maintaining equipment by filtering contaminants from oils and lubricants.

Healthcare and Biopharmaceutical Applications

In the healthcare sector, porous filters are crucial for maintaining sterility and purity. They are used in air and liquid filtration, ensuring that bacteria and other harmful particles do not contaminate products or environments, critical in biopharmaceutical manufacturing.

Benefits of Using Porous Filters

Efficiency and Reliability

One of the primary advantages of porous filters is their efficiency. They are designed to operate continuously with minimal maintenance, providing reliable filtration solutions that reduce downtime and operating costs. Lvyuan’s commitment to quality ensures that their filters meet industry standards, backed by CE, ROHS, and SGS certifications.

Cost-Effectiveness

Porous filters are not only effective but also economical. Their durability and ability to be cleaned and reused make them a cost-effective solution for long-term applications. By investing in high-quality filters like those from Lvyuan, companies reduce replacement costs and ensure consistent performance.

Environmental Impact

An often overlooked benefit of porous filters is their positive environmental impact. By improving filtration efficiency and reducing waste, they contribute to more sustainable industrial practices. Lvyuan’s dedication to innovation further enhances the environmental benefits of their filtration solutions.

Innovations in Porous Filter Technology

Advancements in Sintered Metal Filters

Lvyuan is at the cutting edge of filter technology, focusing on innovations in sintered metal filters. These advancements allow for greater customization and performance optimization, catering to the specific needs of different applications and industries.

OEM & ODM Services

With a strong focus on OEM and ODM services, Lvyuan is capable of designing and manufacturing customized filtration solutions. This approach ensures that industries have access to filters that meet their precise requirements, enhancing productivity and efficiency.

How to Choose the Right Porous Filter

Understanding Industry Requirements

Selecting the right porous filter involves understanding the specific needs of the application. Consider factors such as temperature, chemical compatibility, and required filtration precision. Lvyuan’s team of experts is available to help clients choose the best filter for their needs, ensuring optimal performance.

Consulting with Filtration Experts

Given the complexity of modern industrial applications, consulting specialists in filtration technology is invaluable. Lvyuan offers expert consultation services to assist clients in navigating their filtration needs, providing solutions that are both effective and cost-efficient.

Conclusion: The Future of Porous Filters

Porous filters are indispensable across industries, offering solutions that enhance productivity, ensure safety, and promote sustainability. As Lvyuan continues to innovate and push the boundaries of filtration technology, they remain committed to providing top-tier products and services to over 1,000 customers in 85 countries.

FAQ Section

What are porous filters used for?

Porous filters are used in filtration, separation, and purification processes across various industries such as food and beverage, healthcare, and petrochemicals.

How do porous filters work?

They work by using a matrix of interconnected pores that allow fluids or gases to pass through while trapping larger particles and impurities.

What materials are commonly used for porous filters?

Common materials include stainless steel and sintered metal, both chosen for their durability and corrosion resistance.

Why are Lvyuan's porous filters preferred?

Lvyuan's filters are preferred due to their high quality, efficiency, cost-effectiveness, and the company's strong focus on innovation and customization.

The Ultimate Guide to 316 Stainless Steel Filter Housing by Lvyuan

How to Clean & Maintain Sintered Metal Filters | Lvyuan

What is sintered pp filter cartridges

The Ultimate Guide to Choosing the Right Fine Mesh Water Filter for Your Needs

Sintered mesh filters

Can sintered mesh filters be customized for specific requirements?

Yes, sintered mesh filters are highly customizable. They can be tailored based on factors such as filtration rating, material composition (e.g., stainless steel, monel), dimensions, and shape to meet the unique needs of different applications.

Porous Plastic Filter

Can sintered porous filter discs withstand high temperatures?

Yes, depending on the material selected (e.g., stainless steel or nickel alloys), sintered porous filter discs can withstand high temperatures, making them suitable for applications involving elevated temperatures.

For company

How do you establish a long-term and positive business relationship?

We maintain high-quality standards and competitive prices to ensure mutual benefits for our customers. We treat every customer with respect, considering them not only as clients but also as friends. We engage in sincere business dealings and aim to build lasting friendships, regardless of their geographical location.

For customization

How can we guarantee quality?

Always take a pre-production sample before mass production.

Our state-of-the-art testing equipment and rigorous adherence to quality control standards ensure that our filter housings and filter elements comply with ISO 9001.

Metal mesh filters

What types of contaminants can sintered wire mesh filter?

Sintered wire mesh can filter a wide range of contaminants, including particles, solids, and impurities from liquids and gases. The filtration efficiency depends on factors such as pore size and material selection.

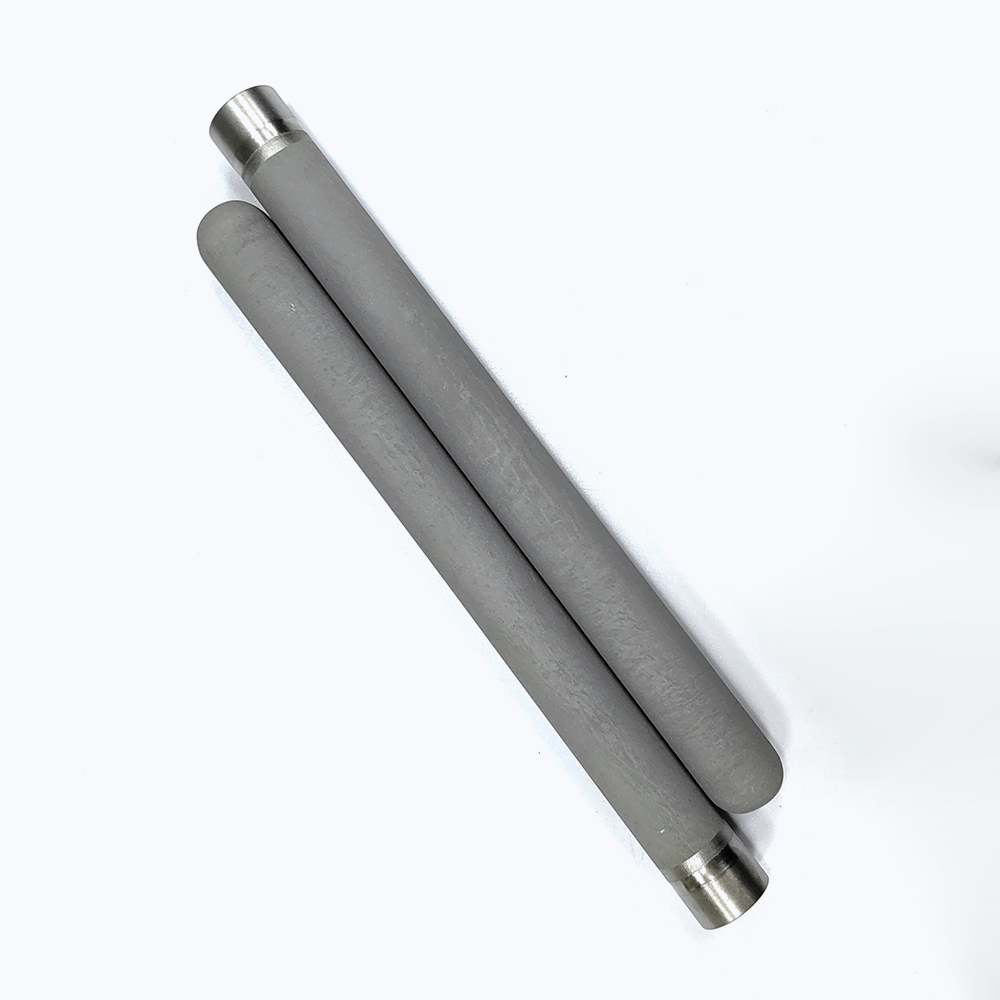

Sintered metal tube

Our Sintered Metal Tube stands as a hallmark of excellence in industrial filtration, offering a robust and efficient solution for various applications.

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions