What is porous filter

- Understanding Porous Filters: An In-Depth Exploration

- What is a Porous Filter?

- The Science Behind Porous Filters

- Material Composition of Porous Filters

- Industrial Applications of Porous Filters

- The Advantages of Using Porous Filters

- Lvyuan's Expertise in Sintered Metal Filters

- The Impact of Porous Filters in Environmental Protection

- Quality Certifications and Global Reach

- Customization and Flexibility with Lvyuan

- Conclusion: The Future of Filtration with Porous Filters

- Frequently Asked Questions

Understanding Porous Filters: An In-Depth Exploration

What is a Porous Filter?

Porous filters are an essential component in the filtration process across various industries. These filters are made from materials with tiny holes or pores that allow for the separation of particles or contaminants from liquids or gases. The construction of these filters ensures efficient filtration and purification, making them indispensable in technological and industrial applications.

The Science Behind Porous Filters

The functionality of porous filters lies in their unique design, consisting of a myriad of interconnected pores. These pores are capable of trapping particles while allowing clean fluid or air to pass through. The size, distribution, and connectivity of these pores determine the efficiency and application suitability of the filter.

Material Composition of Porous Filters

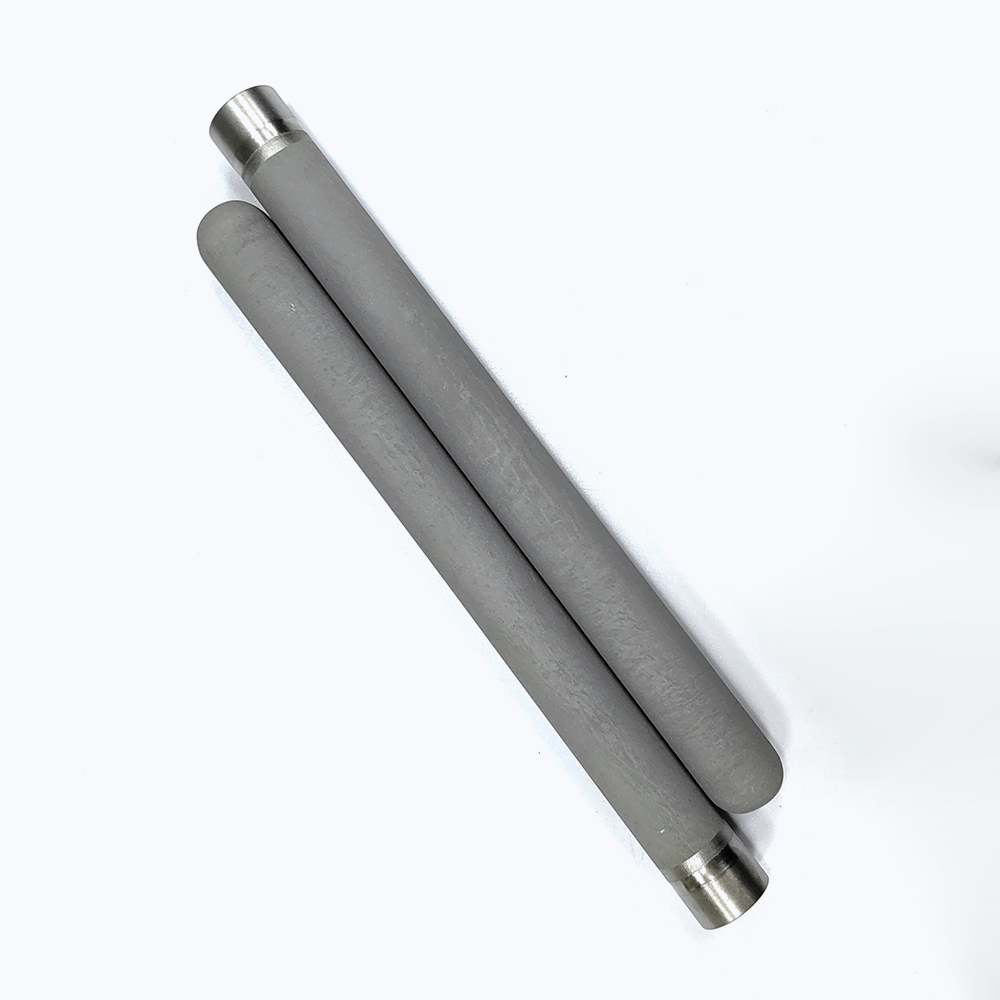

Porous filters can be composed of various materials, such as sintered metal, ceramics, or polymers. Each material offers distinct advantages, catering to specific industrial requirements. For instance, sintered metal filters are renowned for their durability and resistance to high temperatures and chemical reactions, making them ideal for demanding environments.

Industrial Applications of Porous Filters

Porous filters serve a pivotal role in numerous industries. In the food and beverage sector, they ensure product purity. In the petrochemical industry, they assist in the separation of impurities from fluids. The medical field employs them for sterilization and purification purposes. Their versatility extends to electronics, where they help maintain the cleanliness of processes.

The Advantages of Using Porous Filters

Utilizing porous filters offers significant advantages. They provide high efficiency in filtering out contaminants, enhancing the quality and safety of the final product. With minimal maintenance requirements, they offer cost-effective solutions. Additionally, their longevity and reliability make them a preferred choice for continuous operations.

Lvyuan's Expertise in Sintered Metal Filters

Guangzhou Lvyuan Water Purification Equipment Co., Ltd., founded in 2009, stands as a leader in the R&D and manufacturing of sintered metal filters. Specializing in stainless steel filter housings, PE filters, and other cartridges, Lvyuan ensures superior filtration solutions tailored to various industry needs.

The Impact of Porous Filters in Environmental Protection

Porous filters contribute significantly to environmental protection by ensuring that harmful particles and pollutants are effectively removed from industrial emissions and waste streams. Their efficiency in maintaining cleaner production processes aligns with global sustainability goals.

Quality Certifications and Global Reach

Lvyuan boasts certifications such as CE, ROHS, and SGS, affirming the quality and safety of its products. With OEM & ODM services, Lvyuan caters to a diverse clientele, having served over a thousand customers across 85 countries. The global reach and acceptance underscore the trust and reliability associated with Lvyuan's products.

Customization and Flexibility with Lvyuan

Understanding that each industry has unique filtration requirements, Lvyuan offers customized solutions. By tailoring the size, material, and configuration of filters, Lvyuan ensures optimal performance and satisfaction for specific applications, maintaining their commitment to excellence and innovation.

Conclusion: The Future of Filtration with Porous Filters

Porous filters stand at the forefront of filtration technology, facilitating clean and efficient industrial processes. As industries evolve, the demand for advanced, reliable filtration systems continues to grow. Companies like Lvyuan are poised to lead this charge, offering innovative solutions that enhance operational efficiency while safeguarding environmental health.

Frequently Asked Questions

How do porous filters work?

Porous filters work by using a network of tiny holes to separate contaminants from liquids or gases. The size and arrangement of these pores determine the filter's efficiency and application.

What industries benefit from porous filters?

Industries such as food and beverage, petrochemical, medical, electronics, and environmental protection benefit from the use of porous filters.

What materials are used in porous filters?

Common materials include sintered metal, ceramics, and polymers.

Why choose Lvyuan for filtration solutions?

Lvyuan is a trusted leader with a proven track record in quality and innovation, offering customized filtration solutions globally.

Discover the Best China Stainless Steel Filter Tube Solutions – Lvyuan

Custom sintered stainless steel filter Manufacturers and suppliers

The Application of Sintered Metal Filters in the Pharmaceutical Industry | Lvyuan

What is sinter cartridge filter

Sintered mesh filters

How can I select the right sintered mesh filter for my application?

To select the right sintered mesh filter, consider factors such as filtration requirements, material compatibility, temperature and pressure conditions, and specific application needs. Consult with the manufacturer for guidance on customization options.

Stainless Steel Pleated Filter Cartridges

What are the main applications of Stainless Steel Pleated Filter Cartridges?

These cartridges are commonly used for polymer melt filtration, high-temperature gas and steam filtration, and filtration of high-temperature liquids and viscous fluids in industries such as petrochemicals, manufacturing, and more.

Porous Plastic Filter

Are sintered porous filter discs suitable for sterile filtration?

Yes, sintered porous filter discs can be designed for sterile filtration applications, especially when made from materials suitable for high-temperature and chemical sterilization methods.

For company

How can we get the quotation of filter cartridges?

Please tell me the model or specification you need, such as material, length, size, industry, etc.

For products

How can I request a quote or get more information about your sintered metal filters?

For inquiries, quotes, or additional information about our sintered metal filters, please contact our sales team through our website or by reaching out to [contact information]. We are happy to assist you with any questions or requirements you may have.

Sintered metal tube

Our Sintered Metal Tube stands as a hallmark of excellence in industrial filtration, offering a robust and efficient solution for various applications.

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions