High-Quality Sintered Metal Filters: Uses, Benefits, and FAQs | Lvyuan

- What Are Sintered Metal Filters?

- Key Features of Sintered Metal Filters

- What Are the Benefits of Using High-Quality Sintered Metal Filters?

- 1. Superior Filtration Efficiency

- 2. Long Service Life

- 3. Versatility

- 4. Cost-Effectiveness

- What Industries Use Sintered Metal Filters?

- 1. Chemical and Petrochemical

- 2. Pharmaceutical

- 3. Food and Beverage

- 4. Automotive

- How Do You Choose the Right Sintered Metal Filter?

- 1. Application Requirements

- 2. Material Compatibility

- 3. Pore Size

- 4. Certifications and Standards

- Frequently Asked Questions About Sintered Metal Filters

- 1. Can Sintered Metal Filters Be Cleaned and Reused?

- 2. What Is the Difference Between Sintered Metal Filters and Mesh Filters?

- 3. Are Sintered Metal Filters Suitable for High-Temperature Applications?

- 4. How Long Do Sintered Metal Filters Last?

- Conclusion

# High-Quality Sintered Metal Filters: Uses, Benefits, and FAQs

Sintered metal filters are essential components in various industrial applications, offering durability, precision, and efficiency. Whether you're in the chemical, pharmaceutical, or food and beverage industry, understanding the benefits and uses of high-quality sintered metal filters can help you optimize your processes. In this blog, we’ll answer some of the most common questions about sintered metal filters and explain why they are a superior choice for filtration needs.

What Are Sintered Metal Filters?

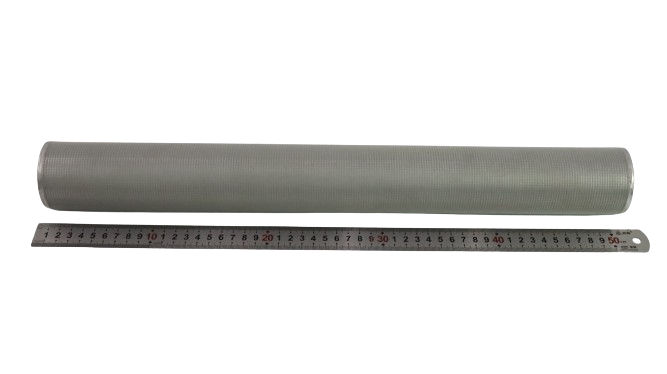

Sintered metal filters are porous materials made by compacting and heating metal powders to form a solid structure with controlled porosity. This process, known as sintering, creates a filter with precise pore sizes, allowing for efficient filtration of liquids and gases.

Key Features of Sintered Metal Filters

- High Durability: Resistant to high temperatures, corrosion, and mechanical stress.

- Customizable Pore Sizes: Available in various micron ratings to suit specific filtration needs.

- Reusable and Cleanable: Can be cleaned and reused, reducing long-term costs.

What Are the Benefits of Using High-Quality Sintered Metal Filters?

High-quality sintered metal filters offer several advantages over traditional filtration methods. Here are some of the key benefits:

1. Superior Filtration Efficiency

Sintered metal filters provide consistent and reliable filtration, removing contaminants with high precision. Their uniform pore structure ensures minimal pressure drop and maximum flow rates.

2. Long Service Life

Made from robust materials like stainless steel, bronze, or nickel, these filters are designed to withstand harsh operating conditions, ensuring a longer lifespan.

3. Versatility

Sintered metal filters are suitable for a wide range of applications, including gas filtration, liquid filtration, and even sound attenuation.

4. Cost-Effectiveness

While the initial investment may be higher, the durability and reusability of sintered metal filters make them a cost-effective solution in the long run.

What Industries Use Sintered Metal Filters?

Sintered metal filters are widely used across various industries due to their reliability and efficiency. Some of the key industries include:

1. Chemical and Petrochemical

Used for filtering corrosive chemicals, catalysts, and gases, sintered metal filters ensure safe and efficient operations.

2. Pharmaceutical

In the pharmaceutical industry, these filters are used for sterilizing liquids and gases, ensuring product purity and compliance with regulatory standards.

3. Food and Beverage

Sintered metal filters are ideal for filtering liquids like beer, wine, and edible oils, maintaining product quality and safety.

4. Automotive

In automotive applications, these filters are used for fuel and oil filtration, enhancing engine performance and longevity.

How Do You Choose the Right Sintered Metal Filter?

Selecting the right sintered metal filter depends on several factors, including:

1. Application Requirements

Consider the type of fluid or gas being filtered, the operating temperature, and the required filtration efficiency.

2. Material Compatibility

Choose a filter material that is compatible with the medium being filtered. For example, stainless steel is ideal for corrosive environments.

3. Pore Size

Select a filter with the appropriate pore size to achieve the desired level of filtration.

4. Certifications and Standards

Ensure the filter meets industry standards and certifications, such as ISO or FDA compliance, for specific applications.

Frequently Asked Questions About Sintered Metal Filters

1. Can Sintered Metal Filters Be Cleaned and Reused?

Yes, sintered metal filters can be cleaned using methods like backflushing, ultrasonic cleaning, or chemical cleaning, making them reusable and cost-effective.

2. What Is the Difference Between Sintered Metal Filters and Mesh Filters?

Sintered metal filters have a more uniform pore structure and higher durability compared to mesh filters, which are prone to clogging and wear.

3. Are Sintered Metal Filters Suitable for High-Temperature Applications?

Yes, sintered metal filters are designed to withstand high temperatures, making them ideal for applications like exhaust gas filtration.

4. How Long Do Sintered Metal Filters Last?

The lifespan of a sintered metal filter depends on the operating conditions and maintenance. With proper care, they can last for several years.

Conclusion

High-quality sintered metal filters are a reliable and efficient solution for a wide range of industrial filtration needs. By understanding their benefits, applications, and selection criteria, you can make informed decisions to optimize your processes. Whether you're looking for durability, precision, or cost-effectiveness, sintered metal filters are an excellent choice.

For more information or to explore our range of high-quality sintered metal filters, contact Lvyuan today!

Surface Treatment Methods of Sintered Metal Filters - Lvyuan

20 Questions for Sintered Metal Filters - Lvyuan

Everything You Need to Know About stainless steel pump housing

What is filter disk

Sintered mesh filters

Can sintered mesh filters be used in corrosive environments?

Yes, sintered mesh filters can be manufactured from corrosion-resistant materials such as stainless steel, making them suitable for use in corrosive environments.

Metal mesh filters

What applications is sintered wire mesh suitable for?

Sintered wire mesh filter finds applications in various industries, including:

• Filtration of liquids and gases.

• Polymer and chemical processing.

• Pharmaceutical and food processing.

• Aerospace and automotive industries.

• Environmental protection and water treatment.

Stainless Steel Pleated Filter Cartridges

What are the advantages of using Stainless Steel Pleated Filter Cartridges?

Advantages include exceptional durability, high-temperature resistance, corrosion resistance, efficient filtration, versatility in applications, customization options, and cost-effectiveness.

Sintered Titanium Filters

What are Sintered Titanium Filters?

Sintered titanium filters are porous metal components created through a sintering process, designed to provide efficient filtration in various applications.

Stainless Steel Cartridge Filter Housing

How do stainless steel cartridge filter housings work?

Stainless steel filter housings operate by passing the process fluid through the filter element, where contaminants are captured on the filter media, allowing the clean fluid to pass through and exit the housing.

Sintered mesh filter

We has been a pioneer in the filtration industry, leveraging global cutting-edge technologies to produce advanced sintered mesh filters. The stainless steel sintered mesh filter stands out as one of the most sought-after products in the market.

Bag filter housing

Sintered powder metal filters

Stainless steel multi cartridge filter housing

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions