High-Quality Sintered Porous Plastic Filters | Lvyuan Innovations

Comprehensive Filtration Solutions with Sintered Porous Plastic

Lvyuan Water Purification Equipment Co., Ltd., established in 2009, is your trusted partner for superior sintered porous plastic solutions. Our filters are meticulously designed to cater to a range of industries including food and beverage, petrochemical, and healthcare. By focusing on innovation and quality, we provide effective filtration, separation, and purification solutions tailored to your needs. Join over 1,000 satisfied clients in 85 countries who rely on Lvyuan for excellence in filtration technology.

Benefits of Sintered Porous Plastic Filters

Sintered porous plastic filters offer remarkable durability and performance. These filters are crafted to withstand extreme environments, proving essential for both liquid and air filtration. The sintering process enhances the structural integrity of the material, providing consistent porosity and making them ideal for precision applications. Trust Lvyuan's filters for their high resistance to temperature variations and chemical exposure, ensuring longevity and reliability in your operations.

Commitment to Quality and Innovation

Lvyuan is dedicated to pioneering advancements in filtration technology. Our sintered porous plastic filters are designed and manufactured in compliance with CE, ROHS, and SGS certifications, guaranteeing safety and efficiency. With a focus on research and development, our products are continuously refined to meet emerging industry needs, offering you the most cutting-edge solutions.

Customized Filtration Solutions with Lvyuan

Understanding that each industry presents unique challenges, Lvyuan provides customizable solutions with OEM and ODM services. Whether you require specific dimensions or unique compositions, our team of experts is ready to develop filters that align with your distinct specifications. Enhance your filtration system with Lvyuan's advanced, tailor-made solutions.

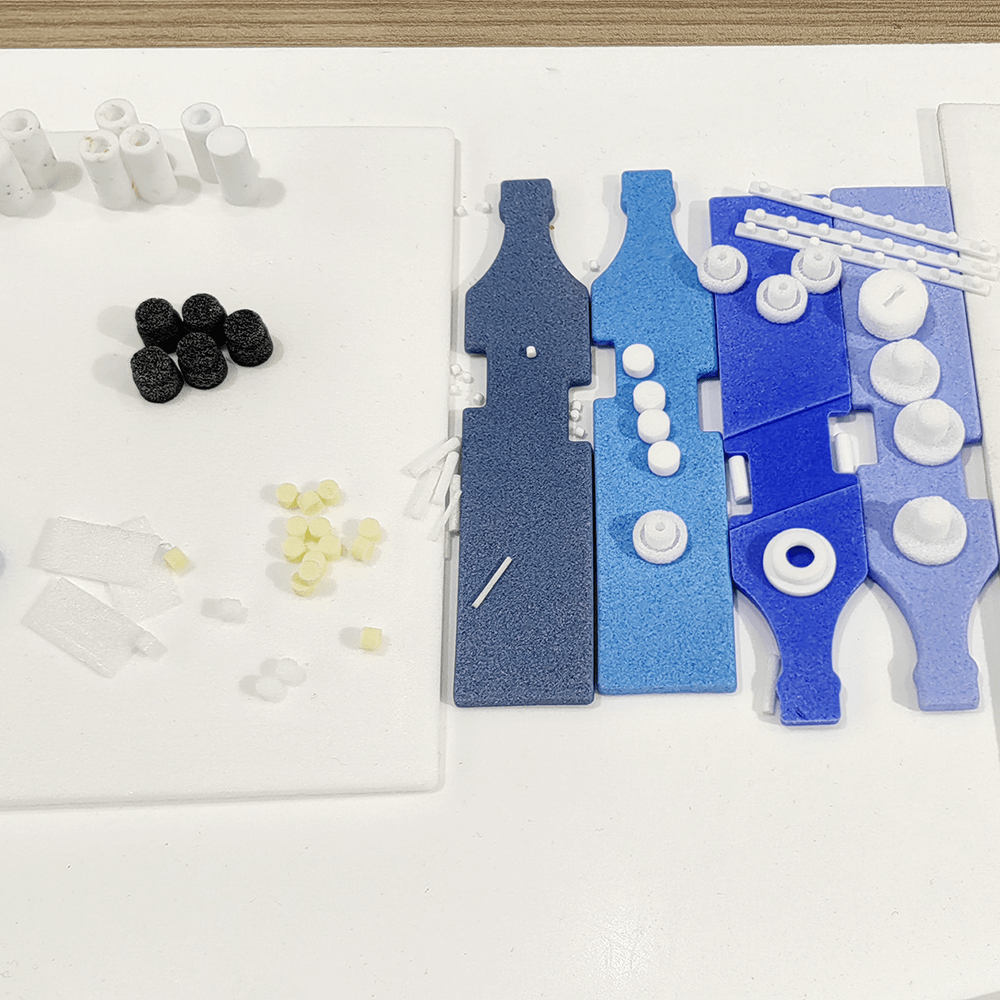

Sintered Porous Plastic Display

- High Filtering Precision

Sinter metal filters provide exceptional filtering precision, with pore sizes ranging from 0.1μm to 10μm. This precision allows for the effective removal of contaminants and particles, ensuring the production of pure and high-quality substances in medical applications.

- Sterile Filtration

Sintered metal filters are capable of sterile filtration, crucial in the production of pharmaceutical ingredients and other applications where maintaining a sterile environment is essential.

- Long Operational Lifespan

Sinter metal filters can be used for an extended period without frequent replacement. With good backwash performance, they can remain in operation for up to 10 years, reducing maintenance requirements and associated costs.

- Global Presence

Our products are trusted by a diverse clientele spanning 85 countries, a testament to the reliability and effectiveness of our solutions in varying industrial contexts.

- Defined Permeability and Particle Retention

These filters offer defined permeability, allowing for controlled flow rates while effectively retaining particles. The ability to regulate permeability ensures optimal filtration performance in medical processes.

Lvyuan main product advantages

• Quality Assurance:

Lvyuan prioritizes quality as a cornerstone of its operations. We adhere to rigorous quality control standards throughout the manufacturing process to ensure that our products meet the highest industry standards.

• Innovative Technology:

We leverage cutting-edge technologies in the design and production of our products. By staying at the forefront of technological advancements, we provide our customers with innovative solutions that meet their evolving needs.

• Diverse Product Range:

Lvyuan offers a comprehensive and diverse range of products, catering to various industries and applications. Our extensive product portfolio allows customers to find solutions tailored to their specific requirements.

• Customization Capabilities:

Recognizing the unique needs of our customers, we provide customizable options for our products. This ensures that our clients receive tailored solutions that align with their individual preferences and applications.

• Competitive Pricing:

We are committed to offering competitive prices without compromising on quality. Our cost-effective solutions enable customers to access high-quality products at reasonable and competitive market rates.

Can Sintered Titanium Filters Withstand Harsh Environments?

Yes, sintered titanium filters exhibit excellent resistance to corrosion from seawater and various chemicals, making them suitable for harsh and aggressive environments.

What types of polymers are used to manufacture sintered plastic porous filters?

Common polymers used in the production of sintered plastic porous filters include polyethylene (PE), polypropylene (PP), polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF), among others.

Can sintered porous filter discs be customized?

Yes, sintered porous filter discs are highly customizable. You can specify pore sizes, material preferences, disc diameter, and other parameters to meet the unique requirements of your application.

What Applications Are Sintered Titanium Filters Suitable For?

Sintered titanium filters are versatile and find applications in water treatment, gas diffusion, chemical experiments, and pharmaceutical processes due to their temperature resistance and corrosion resilience.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions