Sintered PP Filter

High-quality polypropylene(PP) is used as the main raw material and sintered by scientific formula, which is compact, strong, light and can withstand high filtration pressure, and the aperture of the cartridge is the same inside and outside, so it is easy to blow back and de-flow, and has good corrosion resistance to acid and broken solvent.

![]() Personalized customization:

Personalized customization:

Whether choosing from these specifications or presenting your unique requirements, Lvyuan ensures a tailored approach to meet your specific needs.

![]() After-Sales Service and Warranty:

After-Sales Service and Warranty:

We offer comprehensive after-sales services, including installation guidance and technical support. Our products also come with a specified warranty period to ensure a worry-free experience for our customers.

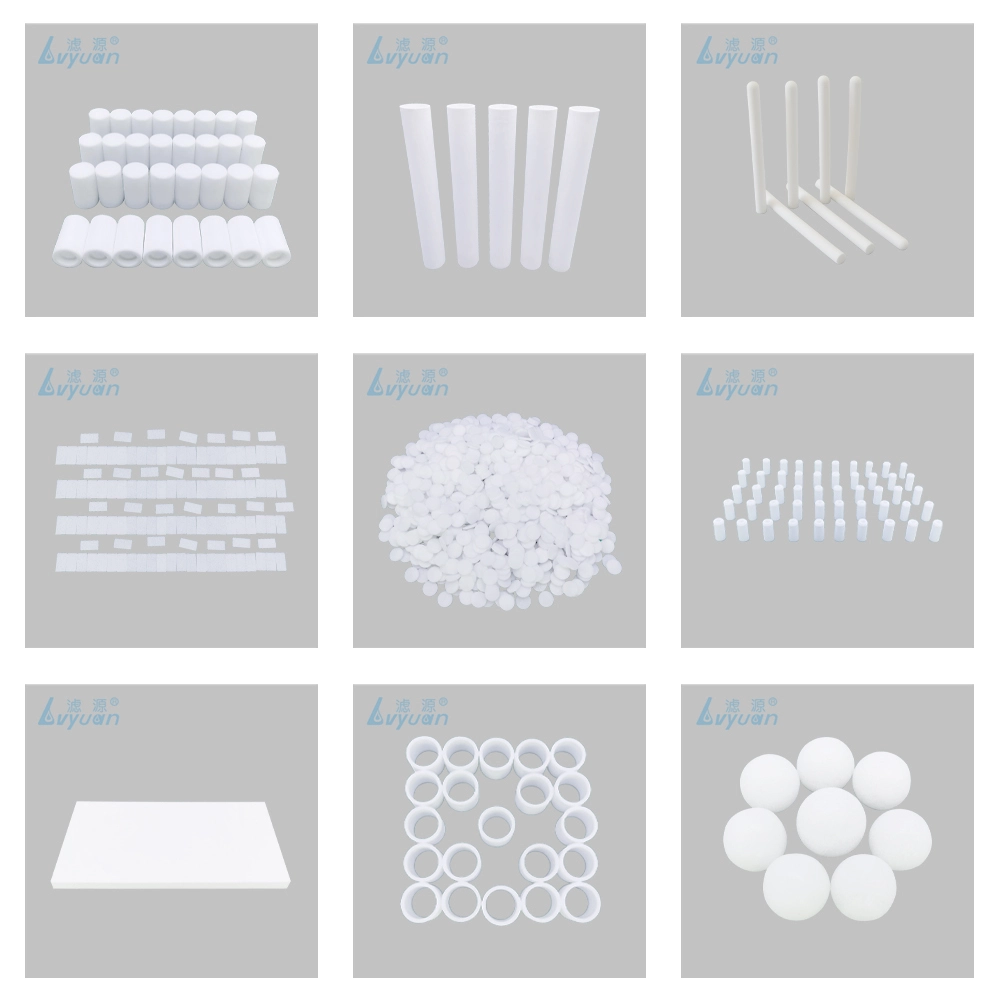

Product description

High-quality polypropylene is used as the main raw material and sintered by a scientific formula, which is compact, strong, light, and can withstand high filtration pressure. The aperture of the cartridge is the same inside and outside, so it is easy to blow back and de-flow, and it has good corrosion resistance to acid and broken solvent. Polypropylene (PP) sintered products include PP sintered cartridge, PP sintered sheet and screen plate, PP sintered filter ball, PP sintered shaped parts, etc.

Parameters

• Technical parameters PP sintered products with uniform pore size distribution, good circulation, and large flux Resistant to strong acids and alkalis, salt, and most organic solvents.

• Easy to blow back, high regeneration efficiency, PP material product temperature resistance of 80 °C, filtration precision of 1 to 200 °C, non-toxic tastelessness, no media off, superior mechanical properties, not easy to damage the raw material in line with GMP and FDA requirements, no adhesive, and a wide range of chemical compatibility.

We’ve got answers.

Browse some answers to our most common questions, or you can drop us a line to ask something else.

Porous Plastic Filter

How do I clean and maintain sintered porous filter discs?

Cleaning methods depend on the material used. For metal discs, methods may include backwashing, ultrasonic cleaning, or chemical cleaning. Polyethylene discs are often cleaned with mild detergents. Regular maintenance ensures a prolonged operational life.

Can sintered porous filter discs be customized?

Yes, sintered porous filter discs are highly customizable. You can specify pore sizes, material preferences, disc diameter, and other parameters to meet the unique requirements of your application.

Are sintered porous filter discs suitable for sterile filtration?

Yes, sintered porous filter discs can be designed for sterile filtration applications, especially when made from materials suitable for high-temperature and chemical sterilization methods.

Can sintered porous filter discs withstand high temperatures?

Yes, depending on the material selected (e.g., stainless steel or nickel alloys), sintered porous filter discs can withstand high temperatures, making them suitable for applications involving elevated temperatures.

What are Porous Metal Filters?

Porous metal filters stand as specialized filtering tools employed in applications where conventional filtration equipment falls short. Typically, metals undergo a sintering process, transforming them into porous or powdered structures, ensuring a more effective filtration process.

Technically, sintering is a metallurgical method applied to solidify metals or alloys into a powdered form. This involves heating the metal or alloy below its melting point to create an intense solid structure with a specific number of pores.

Here are some main types of porous filters used across various industrial applications:

• Sintered Porous Metal Filter: These filters boast pores for effective filtration and are crafted to withstand high pressure and mechanical stress. Manufacturing involves sintering plastic and high molecular polymer powder at elevated temperatures.

• Porous Stainless Steel: Utilizing grade 316 steel, these high-performance filters offer excellent pressure and temperature resistance, ideal for harsh conditions.

• Porous Discs: Shaped as filter discs, these filters are designed with precise pore sizes and numbers for efficiency in specific applications.

• Sintered Metal Filter: Tailored for high industrial and commercial demands, these filters accommodate the effective filtration of gases, liquids, and semi-solids.

• Porous Bronze Filter: Manufactured with spherical bronze powder, these filters excel in noise reduction and turbulence-proofing, making them a reliable choice across various industries.

How do I clean and maintain sintered plastic porous filters?

Sintered plastic porous filters can be cleaned using various methods, such as backwashing, ultrasonic cleaning, chemical cleaning, and steam sterilization, depending on the type of contaminants and the filter's compatibility with cleaning agents. Regular maintenance, such as inspection and replacement of filters, is essential to ensuring optimal performance.

Want to talk to us

Get in touch

Please fill in the form below. We aim to reply within 1 business day.

Sintered PE Filter

Lvyuan Sintered polyethylene PE pipe or plate can be used for vacuum filtration, pressure filtration or gravity filtration.

Sintered PTFE Filter

The sintered PTFE filter is a high-performance filtration solution designed to effectively remove impurities and contaminants from fluids, offering exceptional chemical resistance and durability in various industrial applications.

PA Filter

Sintered PA filter cartridge is made of high quality polymer polyethylene as the main raw material and carbon fiber sintered by scientific formula. It is compact, sturdy, light and can withstand high pressure, non-toxic and tasteless, and has good corrosion resistance to acid and alkali.

Sintered PP Filter

High-quality polypropylene(PP) is used as the main raw material and sintered by scientific formula, which is compact, strong, light and can withstand high filtration pressure, and the aperture of the cartridge is the same inside and outside, so it is easy to blow back and de-flow, and has good corrosion resistance to acid and broken solvent.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions