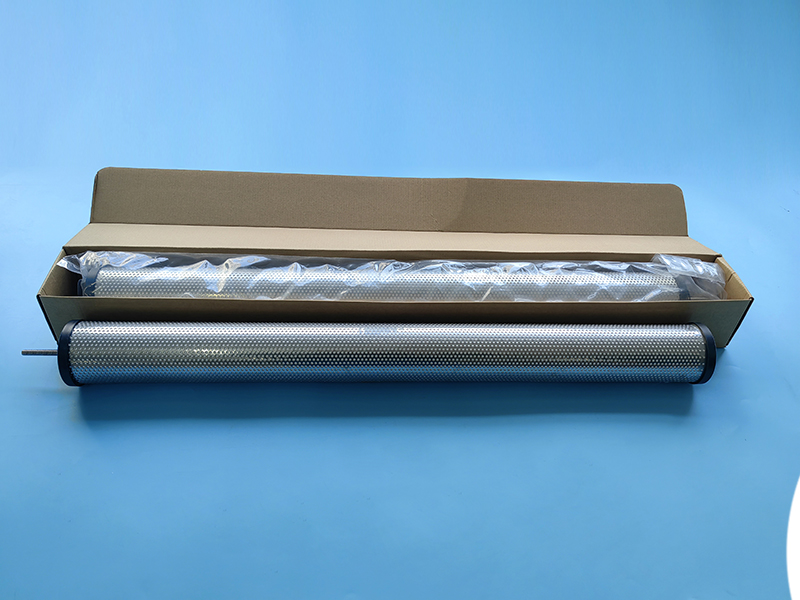

Case Study: LY-48T/304 Compressed Air Filter Cartridge (1 Micron, DN80)

Introduction: In the world of industrial filtration, compressed air quality is crucial for the longevity and performance of machinery, ensuring smooth operations and reduced downtime. This case study highlights the use of the LY-48T/304 compressed air filter cartridge, a 1-micron filter element designed for DN80 filter housings, tailored to meet the needs of a customer seeking high-efficiency filtration in their compressed air systems.

Customer Background: Our client, an industrial manufacturer located in China, specializes in heavy machinery production. Their operations involve a variety of pneumatic systems, where the quality of compressed air directly affects the precision of their equipment. They were facing issues with air quality, including moisture and particulate contamination, which impacted machine performance and led to increased maintenance costs.

Product Overview: The LY-48T/304 compressed air filter cartridge is a 1-micron filtration solution, designed to remove fine particles and moisture from compressed air systems. Constructed from high-quality SS304 material, the filter is built for durability and resistance to harsh industrial environments. Its 1-micron filtration capacity ensures that even the smallest contaminants are effectively removed, leading to cleaner air and better operational efficiency.

Specifications:

· Model: LY-48T/304

· Filtration Accuracy: 1 micron

· Nominal Size: DN80

· Material: Stainless Steel 304 (SS304)

· Filter Housing Compatibility: E7-48

· Application: Compressed air systems

· Operating Pressure: 4-6 bar

· Operating Temperature: 5°C - 60°C

Customer Needs: The customer required a reliable filtration system that could meet the stringent demands of their pneumatic machinery. The main objective was to achieve higher air purity, reduce contaminants, and minimize the risk of system failure or equipment wear. They needed a filter solution that could handle their system's high-volume compressed air while maintaining consistent filtration performance.

Solution Provided: We recommended the LY-48T/304 compressed air filter cartridge, perfectly suited for DN80 filter housings. The cartridge’s 1-micron filtration precision effectively removes dust, oil aerosols, and moisture, ensuring that only clean air is supplied to the machinery. Its compatibility with the E7-48 filter housing made installation seamless, and the robust SS304 construction provided long-lasting performance in the demanding industrial environment.

Results: Upon installation of the LY-48T/304 filter, the customer reported a significant improvement in compressed air quality. The 1-micron filtration level ensured that contaminants were consistently removed, leading to smoother operations and reduced wear on machinery. Over time, the customer observed fewer system failures, lower maintenance costs, and enhanced equipment lifespan. Moreover, the efficiency of the pneumatic systems was notably increased, leading to better overall productivity.

Conclusion: The LY-48T/304 compressed air filter cartridge proved to be an ideal solution for the customer’s filtration needs. By choosing a high-quality, stainless steel cartridge with 1-micron filtration, they were able to meet the rigorous demands of their compressed air system, improving operational efficiency and reducing maintenance costs.

What is Sintered Metal Filter? Complete Guide

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

Choosing Sintered Filters: An Overview for Industrial Applications

What is a Sintered Metal Filter Disc? A Comprehensive Guide

What Are Sintered Metal Filters and How Do They Work?

Sintered Metal Filter

How can I select the right industrial sintered filter cartridge for my application?

Consult with the manufacturer or supplier, providing details about your specific requirements, such as filtration needs, operating conditions, and industry standards, to receive guidance on selecting the most suitable cartridge for your application.

Sintered Titanium Filters

How Can Machinability of Sintered Titanium Filters be improved?

Machinability can be enhanced by selecting high-speed machining tools, creating conducive cutting environments, and using high-quality cutting tools to optimize cost, surface finishing, and integrity.

Sintered Powder Filters

Are sintered powder filters reusable?

Many sintered powder filters are designed to be reusable. They can be cleaned through backwashing or other methods, contributing to their cost-effectiveness and sustainability.

For customization

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Sintered mesh filters

How can I select the right sintered mesh filter for my application?

To select the right sintered mesh filter, consider factors such as filtration requirements, material compatibility, temperature and pressure conditions, and specific application needs. Consult with the manufacturer for guidance on customization options.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions