What Are Sintered Metal Filters and How Do They Work?

- 1. Intro to Sintered Metal Filters

- 2. Production Refine: Powder Metallurgy and Sintering

- 3. Material Science and Resulting Porous Framework

- 4. Secret Performance Characteristics

- 5. Pore Size Control and Filtration Scores

- 6. Applications Throughout Trick Industries

- 7. Upkeep, Regrowth, and Life Span

- 8. Relative Evaluation with Alternate Purification Technologies

-

1. Intro to Sintered Metal Filters

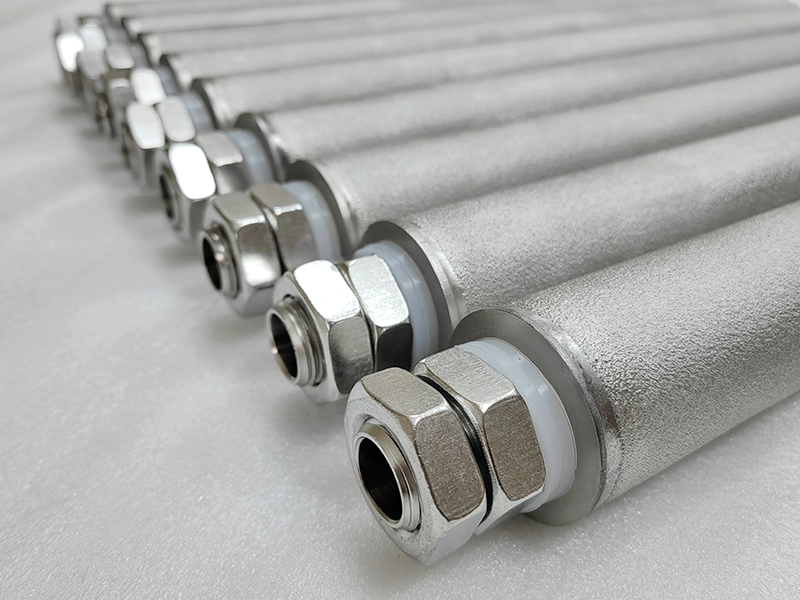

Sintered metal filters are robust, high-performance purification media made from metal powders. Unlike woven or coarse filters, they have an inflexible, interconnected permeable structure created by sintering. Sintering warms compacted steel powder listed below its melting point, bonding particles via diffusion to produce a steady framework with controlled pores.

Made up generally of a single metal or alloy powder, typical products include stainless-steel (316L, 304L), bronze, nickel alloys (Monel, Hastelloy), and titanium, chosen for buildings like deterioration resistance, high-temperature stamina, or biocompatibility.

Filtration occurs by means of surface filtration (particles bigger than surface pores retained) and depth purification (smaller sized particles caught within the tortuous pore network). The stiff framework maintains steady pore dimension under pressure, making sure consistent efficiency.

2. Production Refine: Powder Metallurgy and Sintering

Production makes use of powder metallurgy and includes:

- Powder Selection: Option of metal powder (make-up, size, shape, purity) dictates last residential or commercial properties, particularly pore dimension and leaks in the structure.

- Creating: Powder is consolidated right into a "green body." Methods consist of Pass away Compaction (straightforward shapes), Isostatic Compaction (attire thickness, complex forms), Extrusion (constant accounts), and Slip Casting (complex shapes, fine powders).

- Sintering: The green body is heated up in a controlled ambience listed below the melting factor. This bonds particles (neck growth), rounds pores, and regulates densification to achieve preferred porosity and strength. Criteria (temperature, time, atmosphere) are essential for pore structure and permeability.

Post-sintering steps like machining might be used for final filter setting up.

3. Material Science and Resulting Porous Framework

Product selection is vital for efficiency.

- Stainless Steels (316L, 304L): Typical for corrosion resistance, toughness, cost. 316L resists pitting/crevice rust (chemical, pharma, food). 304L for much less hostile usages.

- Bronze: Lower temp/corrosion uses (silencers, basic filtration). Much more economical however much less strong/resistant than SS.

- Nickel Alloys (Monel, Hastelloy): Exceptional resistance to rough chemicals, high temps. Monel resists seawater/acids. Hastelloys stand up to hostile media (chemical processing).

- Titanium: Excellent deterioration resistance (oxidizing, chlorides), biocompatibility. Used sought after chemical, medical, aerospace.

Sintering criteria regulate the permeable structure:

- Porosity: Quantity fraction of pores (20-50%). Higher porosity usually means higher leaks in the structure yet reduced stamina.

- Pore Size Circulation: Range/frequency of pore sizes, critical for efficiency.

- Leaks in the structure: Alleviate of liquid flow.

Powder attributes, developing stress, and sintering control these criteria, tailoring filters for details demands. Finer powders/lower sintering yield smaller pores; coarser powders/higher sintering yield larger pores.

4. Secret Performance Characteristics

Filter efficiency is based upon:

- Filtering Effectiveness: Capability to remove bits. Outright Score: Largest bit dimension theoretically eliminated (100%). Nominal Ranking: Effectiveness at a certain dimension (e.g., 90%), much less exact. Beta proportion ($ \ beta$) measures efficiency.

- Stress Decline: Pressure distinction across filter for flow. Lower is much better. Regulated by fluid residential or commercial properties, filter measurements, and leaks in the structure (Darcy's Law). Obstructing rises pressure drop.

- Mechanical Toughness: Rigid framework stands up to high differential stress (burst/collapse stress). Influenced by product, porosity, sintering.

- Resistance to Heats and Stress: Metal nature allows procedure past polymer restrictions. Minimal by alloy buildings and real estate design.

- Chemical Compatibility: Broad, relies on alloy (SS, Ni alloys, Ti take care of aggressive chemicals).

5. Pore Size Control and Filtration Scores

Pore dimension control is essential:

- Powder Fragment Dimension: Most considerable variable. Finer powder = smaller sized pores.

- Compaction Pressure: Higher pressure reduces first gap space, possibly smaller sized pores.

- Sintering Criteria: Temp/time influence bonding and densification, influencing pore size/porosity.

Filtration ratings are established by examinations:

- Bubble Point Test: Price quotes biggest pore dimension (least restricted).

- Gas Leaks In The Structure Examination: Procedures total permeability.

- Liquid Displacement Examination: Steps pore dimension circulation.

- Bit Challenge Examinations: Determine effectiveness and Beta proportions, resulting in Absolute/Nominal scores.

Outright rankings assure removal at a size; Nominal rankings are much less specific.

6. Applications Throughout Trick Industries

Quality make sintered steel filters vital sought after applications:

- Chemical Handling: Catalyst recovery, filtering system aggressive/high-temp fluids, shielding tools. Cleanable for strong recovery.

- Pharmaceuticals: Sterilized gas, API filtration, process liquid explanation. Robust for steam sanitation (autoclave, CIP/SIP).

- Oil & Gas: Wellhead purification (sand), generated water, protecting pumps/valves in high pressure/temp.

- Food & Beverage: Explanation, particle removal, heavy steam filtration. Resilient, cleanable for hygiene.

- Automotive: Fuel/hydraulic filters, withstand vibration/temp/pressure.

- Aerospace: Hydraulic/fuel/pneumatic systems. High strength-to-weight, reliability in severe conditions.

- Power Generation: Condensate polishing, boiler feedwater filtering to secure wind turbines. High-temp resistance.

Their capacity to manage high pressure/temp, corrosive chemicals, and be cleansed drives their use over options.

7. Upkeep, Regrowth, and Life Span

A crucial advantage is cleanability/regenerability, prolonging service life. Approaches:

- Backflushing: Reverse circulation of tidy liquid displaces bits.

- Chemical Cleansing: Solvents/acids/bases dissolve/loosen foulants.

- Thermal Cleansing: High heat burn natural contaminants.

- Ultrasonic Cleaning: Energy displaces particles in a bath.

Service life depends on: Particulate tons, Foulant nature, Chemical environment, Temp/Pressure cycling, Cleaning up efficiency.

Greater first price is commonly balanced out by lengthy service life and regenerability, causing reduced complete cost of possession.

8. Relative Evaluation with Alternate Purification Technologies

Sintered metal filters stand out where others are limited:marine desalination systems

| Function | Sintered Metal Filters | Woven Cord Mesh Filters | Ceramic Filters | Polymer Membrane layers |

|---|---|---|---|---|

| Material | Metals/Alloys | Steels | Ceramics | Polymers |

| Framework | Inflexible, porous (sintered) | Woven cords | Inflexible, porous (sintered) | Thin, permeable film |

| Filtration Concept | Surface area & Deepness | Mostly Surface area | Surface & Deepness | Surface |

| Pore Dimension Control | Powder, compaction, sintering | Wire/weave | Bit dimension, binder, sintering | Casting/stretching |

| Filtering Rating | Absolute & Nominal (0.5-200 µm+) | Outright (1-1000 µm+) | Outright & Nominal (0.1-50 µm+) | Absolute (0.01-10 µm) |

| Mechanical Strength | Very High | Moderate (can warp) | High yet Brittle | Reduced (flexible) |

| Temperature level Limitation | Really High | High | Very High | Reduced to Moderate |

| Stress Limitation | Very High | Moderate | High | Low to Moderate |

| Chemical Resistance | Exceptional (depends on alloy) | Exceptional (depends on alloy) | Outstanding (relies on ceramic) | Variable (depends on polymer) |

| Cleanability/Regen. | Outstanding | Excellent | Good | Limited (frequently irreversible fouling) |

| Cost | High Initial | Modest Preliminary | High Preliminary | Low to Modest Initial |

| Service Life | Very Long (with cleansing) | Modest to Lengthy | Long | Brief to Moderate (frequently disposable) |

Trick Takeaways: Sintered steel offers superior strength and deepness filtering vs. woven mesh. Much more ductile than brittle ceramics, and far surpass polymer limitations for temperature, stress, and chemical resistance, despite polymers supplying finer purification. They load a particular niche for requiring, severe atmospheres where resilience and regenerability are critical.

What is Sintered Metal Filter? Complete Guide

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

Choosing Sintered Filters: An Overview for Industrial Applications

What is a Sintered Metal Filter Disc? A Comprehensive Guide

5 Benefits of Using Titanium Filters for Filtration

Stainless Steel Pleated Filter Cartridges

Are these pleat cartridges corrosion-resistant?

Yes, the use of stainless steel (SS 304 or SS 316L) provides excellent corrosion resistance, making the cartridges suitable for applications where exposure to corrosive substances is a concern.

Sintered Metal Filters

Can sintered metal filters be cleaned and reused?

Yes, sintered metal filters are designed to be cleaned and reused. Their durability and resistance to fouling make them suitable for applications where filter cleaning is necessary.

Stainless Steel Cartridge Filter Housing

What is a stainless steel cartridge filter housing?

The 304 or 316 stainless steel cartridge filter housing is a durable enclosure designed to hold filter cartridges or filter bags for the filtration of liquids or gases in industrial processes.

Sintered Titanium Filters

Do Sintered Titanium Filters Offer High Flow Rates?

Yes, sintered titanium filters support high flow rates at low-pressure drops, optimizing efficiency and ensuring consistent filtration performance.

Porous Plastic Filter

What pore sizes are available for sintered plastic porous filters?

Sintered plastic porous filters are available in a wide range of pore sizes, typically ranging from submicron to several hundred microns, allowing for precise control of filtration performance and particle retention.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Sintered titanium filter

Discover the efficiency and versatility of our sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions