Choosing Sintered Filters: An Overview for Industrial Applications

- 1. Introduction to Sintered Filters

- 2. Defining the Filtration Application and Refine Problems

- 3. Defining Contaminant Qualities and Elimination Needs

- 4. Developing Performance Standard and System Constraints

- 5. Assessing Product Compatibility and Structural Stability

- 6. Picking the Appropriate Sintered Material and Pore Structure.

- 7. Thinking About Filter Component Style and System Setup.

- 8. Recognition, Checking, and Long-Term Operational Variables

1. Introduction to Sintered Filters

Sintered filters are porous materials made by bonding powder fragments with warm and pressure (sintering). This develops a rigid, interconnected pore structure efficient for separating solids from liquids or gases. Unlike various other media, sintered filters use stable, uniform pores for precise purification. They catch particles larger than their pore size on the surface or within the media.

Benefits consist of high mechanical strength, resilience, and resistance to heats and corrosive chemicals. They are frequently cleanable and reusable, supplying prolonged life and reduced overall price compared to non reusable choices.

Negative aspects include higher ahead of time expense, possible need for specialized cleansing devices, and much longer producing times. Ceramic kinds can be vulnerable, and steel kinds are much heavier.

Products include steels (stainless-steel, bronze, titanium, nickel alloys), ceramics (alumina, silicon carbide), glass, and polymers (polyethylene, PTFE). Material selection effects performance, resistance, strength, and cost.

2. Defining the Filtration Application and Refine Problems

Selecting a sintered filter begins with comprehending the application and procedure conditions: the tool (liquid/gas), the details process, and the operating atmosphere.

Secret parameters:

- Medium Kind: Liquid or gas? Impacts filtering devices and pressure decrease.

- Certain Refine: Context issues (e.g., stimulant recovery vs. clean and sterile purification).

- Temperature level: Important for product choice. Metals and porcelains manage heats (hundreds to over 1000 ° C), while plastics are restricted (around 150 ° C). High temperatures lower polymer chemical resistance.

- Pressure: Figures out required filter toughness. Sintered metals are solid for high-pressure use.

- Circulation Price: Influences filter size and system configuration. Higher prices require larger filter areas.

- Chemical Make-up: Necessary for product compatibility (acids, bases, solvents, salts).

Defining these specifications limits appropriate materials and styles.

3. Defining Contaminant Qualities and Elimination Needs

Defining the impurity is vital: its nature, properties, and required removal level.

Key impurity properties:

- Pollutant Kind: Strong particles, aerosols, stimulants? Influences filtration device (surface area vs. depth).

- Particle Size Circulation (PSD): Establishes called for pore size. Sintered metal pores range from submicron to numerous microns, regulated by powder size and sintering. Filtering scores differ by application and media quality.

- Concentration: Influences filter loading and cleansing frequency. High concentrations increase blocking.

- Particle Shape and Thickness: Influence interaction with media and cleaning up effectiveness.

Elimination demands define desired efficiency:

- Outright Filtration Score: Dimension of largest particle travelling through. Sintered steels can achieve high capture efficiency (99.9%+).

- Beta Ratio: Filter effectiveness at a specific bit size.

- Target Focus: Optimum allowable impurity degree in filteringed system stream.

Recognizing contaminants and requirements ensures selecting a filter with proper pore dimension and efficiency. Numerous approaches measure pore dimension distribution (e.g., nitrogen adsorption, mercury breach, bubble factor).

4. Developing Performance Standard and System Constraints

Filter selection must take into consideration efficiency criteria and system restrictions.

Trick performance standards:

- Maximum Allowable Pressure Decline: Limitations filter filling before cleaning/replacement. Quick increases suggest clogging. Surpassing limitations can damage the filter.

- Required Throughput: Quantity refined each time. System has to handle this within stress decline limitations.

- Wanted Filter Life-span: Anticipated life prior to substitute, influenced by pollutant, cleaning, and material degradation.

- Cleanability and Regeneration Potential: Ease and performance of cleansing (e.g., backflushing) effect expenses and downtime.

- Mechanical Toughness at Solution Temperature Level: Filter needs to withstand running temperature and pressure stresses.

System restrictions:

- Physical Area Limitations: Dictates filter housing and aspect dimension.

- Integration Demands: System must fit existing equipment and controls.

- Material Compatibility of Housing and Ancillary Elements: Housing, seals, and so on, must work with process conditions.

Clear standards and restraints make certain the filter satisfies requirements and runs efficiently within the system. Anticipating models can estimate stress decrease and blocking.

5. Assessing Product Compatibility and Structural Stability

Chemical compatibility and structural honesty are critical for trusted performance.

Chemical Compatibility: Material must resist degradation from the process stream, particularly with aggressive chemicals, high temperatures, or stress.

- Sintered Metal Filters: 316L stainless steel prevails, immune to many chemicals but vulnerable to tension rust breaking. Alloys like Hastelloy C-276 supply far better resistance for requiring uses. Compatibility graphes are guides; screening is suggested.

- Sintered Ceramic Filters: Alumina, silicon carbide, zirconia, and so on, provide high chemical stability and resistance to acids/alkalis. Sintered glass is likewise resistant.

- Sintered Polymer Filters: Compatibility depends on the polymer. PTFE supplies wide resistance. PVDF stands up to oxidizers/solvents. UHMW-PE withstands acids/alkalis however has lower temperature level limitations. PE/PP resist acids/bases yet not strong solvents. PEEK resists numerous fluids however can swell in some solvents. Raised temperatures decrease polymer resistance. Evaluating is critical. Adjustments can enhance solvent resistance.

Architectural Stability: Filter needs to stand up to stress, vibration, and thermal cycling.

- Sintered Metal Filters: Known for strength, ideal for high pressure. Welded building boosts effectiveness.

- Sintered Ceramic Filters: High solidity and mechanical resistance, however can be much more delicate than metal. SiC and Si3N4 provide high stamina and resistance to wear/thermal impacts.

- Sintered Polymer Filters: Solvent direct exposure can decrease strength. Sintered metals like DMLS 316L supply high tensile toughness.

Assessing both guarantees the filter does reliably under specific problems.

6. Picking the Appropriate Sintered Material and Pore Structure.

Product and pore structure selection manufactures previous steps based upon application, problems, impurities, and efficiency.

Material Selection: .

Driven by temperature, chemical setting, and stamina.

- High Temperature/Pressure: Sintered steels (stainless-steel, nickel alloys, high-temp alloys) and porcelains are primary choices.

- Destructive Environments: Corrosion-resistant alloys (Hastelloy) and PTFE are liked. Sintered glass is additionally immune.

- Biocompatibility: Some steels and porcelains match pharma/medical usage.

- Cost: Bronze is usually cheapest metal. Stainless-steel equilibriums cost/performance. Metals/ceramics are typically much more pricey than plastic/glass.

Pore Framework Selection: .

Based on pollutant size, nature, and called for effectiveness.

- Particle Dimension: Dictates called for filtering score. Sintered metals provide broad pore dimension range, managed by producing parameters.

- Filtration System: Smaller sized pores/depth framework for great fragments (diffusion/interception). Larger pores/surface filtering for larger fragments (impaction).

- Circulation Rate/Pressure Decrease: Bigger pores mean reduced stress decline however reduced effectiveness. Fiber metal media have greater porosity, lower pressure decline. Multi-layered media boost dirt capability.

- Cleanability: Uniform pore network aids cleansing (backwashing).

Choice entails trade-offs in between performance, pressure drop, price, and compatibility. Multi-layered media or maximized design can aid.

7. Thinking About Filter Component Style and System Setup.

Aspect style and system setup integrate product and pore framework based on application, performance, and maintenance.

Filter Component Style: .

Sintered media forms numerous forms:.

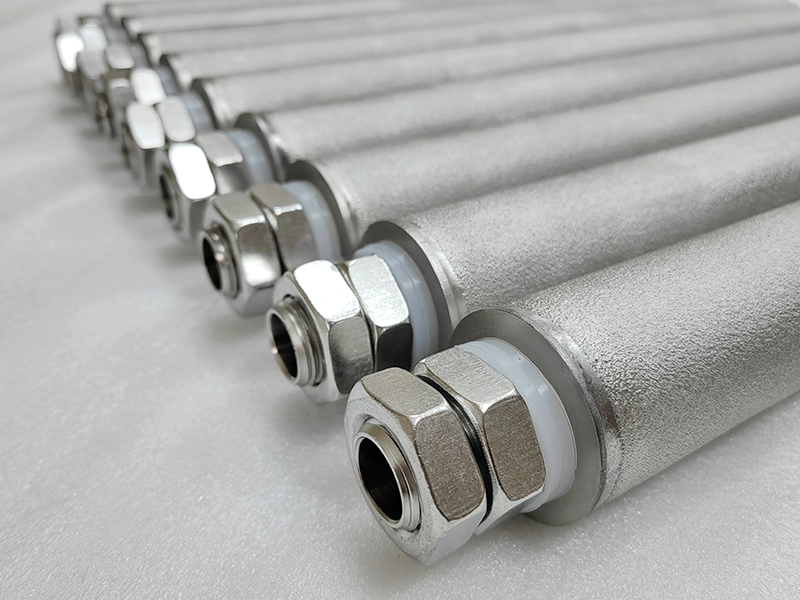

- Cartridges: Cylindrical, often pleated/multi-layered for big location in small volume.

- Discs: Flat, circular for smaller sized systems.

- Tubes: Round for high pressure/temperature.

Style effects location, circulation course, strength, and cleanability. Multi-layered designs improve dust ability. Media residential or commercial properties are engineered for performance and backwash. Cartridges are often bonded for effectiveness.

System Setup: .

Just how aspects are housed and processes taken care of.

- Single/Multi-Element Housing: Single for little circulations, multi for higher flows/redundancy. Multi-core rises location.

- Backflush Ability: Turns around circulation for in-situ cleaning. Gas-assisted backwash is effective. Optimum backflush utilizes suitable liquid at greater pressure. Quantity and frequency require optimization.

- Continual Circulation: Dual/triple systems allow constant procedure throughout cleaning.

- Automation: PLC control and sensing units can automate backwash cycles.

- Flow Control: Stops damage from high flow adventures.

Layout aims for needed filtrate quality, marginal backwash, and maximum throughput. Filter cake can improve efficiency. Real estates are usually carbon steel. Various flow paths (outside-in, inside-out) fit different fluids/contaminants.

8. Recognition, Checking, and Long-Term Operational Variables

Final steps entail confirming efficiency and thinking about long-lasting procedure.

Validation and Screening: .

- Pilot Examining: Crucial to confirm performance with actual liquid under reasonable problems. Verifies design, ability, and usefulness. Requires in-depth method, evaluation, and data recognition. Address limitations like small elements.

- Treatability Studies: Much shorter researches to verify basic information and dressmaker pilot examinations.

- Necessary Factors To Consider: Quick lab analysis, well water disposal, pumping at layout flow for representative water. Test during highest possible impurity levels.

- Sampling and Evaluation: Comprehensive prepare for criteria like TSS, BOD, bit distribution.

- Particle Retention Testing: Challenges filters with fragments at max flow to identify effectiveness.

- High-Temperature Facilities: Specialized testing under high temperature/pressure with real contaminants.

Long-Term Operational Aspects: .

- Cleansing Procedures: Efficient, repeatable cleansing keeps performance and extends life. Techniques include backflushing, ultrasonic, chemical, thermal, and so on. Option depends on product, pollutant, process. Calcination for high-temp regrowth.

- Regeneration Prospective: Capability to restore efficiency effects cost-effectiveness. Monitor pressure recovery after backwash.

- Predicting Operational Life Expectancy: Take into consideration pollutant lots, cleaning efficiency, degradation (corrosion, creep-fatigue). Lasting information and predictive designs help organizing.

- Maintenance Organizing: Routine monitoring (pressure decrease), cleaning cycles, and evaluation prevent blocking and enhance efficiency. Arranged aspect substitute is common.

- Filter Efficiency Examination: Constantly evaluate efficiency and strength. Online efficiency (onward circulation time/ overall cycle time) indicates system performance.

Recognition and considering long-term factors ensure reputable, efficient, and affordable sintered filtration. Clear communication is vital throughout testing.

What is Sintered Metal Filter? Complete Guide

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

What is a Sintered Metal Filter Disc? A Comprehensive Guide

What Are Sintered Metal Filters and How Do They Work?

5 Benefits of Using Titanium Filters for Filtration

Stainless Steel Pleated Filter Cartridges

Are these pleat cartridges corrosion-resistant?

Yes, the use of stainless steel (SS 304 or SS 316L) provides excellent corrosion resistance, making the cartridges suitable for applications where exposure to corrosive substances is a concern.

Porous Plastic Filter

What pore sizes are available for sintered plastic porous filters?

Sintered plastic porous filters are available in a wide range of pore sizes, typically ranging from submicron to several hundred microns, allowing for precise control of filtration performance and particle retention.

Metal mesh filters

What are the key advantages of sintered wire mesh filter?

• High Strength: The sintered wire mesh filter exhibits excellent mechanical strength.

• Uniform Porosity: The sintering process creates a uniform pore structure for efficient filtration.

• Temperature Resistance: Suitable for applications with high temperatures.

• Easy to Clean: Can be cleaned and reused multiple times.

• Chemical Resistance: Resistant to corrosion and chemical exposure.

For company

How is production capacity?

• Sintered metal filters: 10,000 sets per month.

• Filter housings: 5000 sets/month.

• PE filters: 100000 pcs/month.

• And our production capacity is growing.

How can we get the quotation of filter cartridges?

Please tell me the model or specification you need, such as material, length, size, industry, etc.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions