Étude de cas personnalisée : Des voleurs en titane fritté pour des clients espagnols

Les solutions de filtration répondant aux exigences de précision de 0,1 micron augmentent la pureté des produits pour les entreprises pharmaceutiques espagnoles.

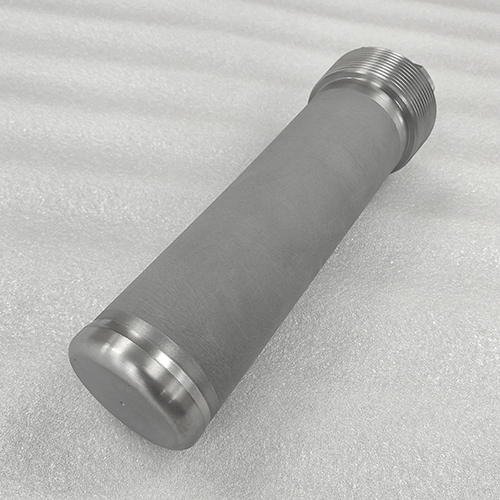

Récemment, Guangzhou Liyuan Water Purification Equipment Co., Ltd. a finalisé avec succès une commande personnalisée de cartouches filtrantes haute performance à noyau en titane fritté pour un client espagnol. Ces cartouches spécialement conçues (φ75 × 250 mm, précision de filtration de 0,1 μm, 250 unités) seront déployées dans les installations européennes du client.ligne de production pharmaceutique.

Contexte du projet et exigences du client

Le client espagnol est spécialisé dans les produits pharmaceutiques haut de gamme et a besoinfiltration de précisionde solutions pharmaceutiques pendant la production. Les cartouches filtrantes utilisées auparavant souffraient d'une précision de filtration insuffisante et de problèmes de déformation, impactant l'efficacité de la production et la qualité du produit.

Le client a spécifié des exigences techniques très détaillées :

- Dimensions de la cartouche: 75 mm de diamètre, 250 mm de longueur hors raccords

- Précision de filtration: 0,1 micron (exigence de précision extrêmement élevée)

- Configuration du connecteur: Connecteurs personnalisés intégrant des structures de tiges de tension

- Quantité: 250 unités

Notamment, la précision de filtration de 0,1 micron se situe dans unegamme de très haute précision, ce qui pose des défis importants au processus de fabrication des cartouches.

Solution et détails techniques

Face à cette commande exigeante, l'équipe technique de Filter Source a réagi rapidement en développant une solution technique détaillée.

Sélection des matériaux et processus de fabrication

La source du filtre utilisepoudre métallique de titane de haute pureté(pureté ≥ 99,7 %) comme matière première, fabriquée grâce à des techniques de métallurgie des poudres avancées. Les éléments filtrants en titane sont réputés pour leursexcellente stabilité chimique,résistance à la corrosion acide/alcaline, ettolérance aux hautes températures, ce qui les rend particulièrement adaptés à l’industrie pharmaceutique.

Le procédé de fabrication comprend le tamisage, le pressage isostatique à froid, puis le frittage à haute température et sous vide poussé. Cette technique garantit que l'élément filtrant possèdedistribution uniforme de la taille des poresetgéométrie des pores stable, garantissant des performances de filtration constantes et fiables.

Dimensions personnalisées et conception de connexion

Le diamètre φ75 mm demandé représente une taille non standard (les diamètres standards incluent généralement Ф22 mm, Ф30 mm, Ф50 mm, etc.). Notre équipe d'ingénieurs a conçu le moule et le procédé de fabrication sur mesure selon les spécifications du client, garantissant ainsi une précision dimensionnelle optimale.

La connexion intègre unstructure de tige de tension, une conception qui améliore la résistance mécanique de la cartouche, empêchant toute déformation ou tout dommage dû aux fluctuations de pression. La tige de tension permet à la cartouche de supporter des différentiels de pression plus élevés (pression différentielle de service maximale jusqu'à 0,6 MPa), prolongeant ainsi sa durée de vie.

Surmonter le défi de la précision de 0,1 micron

La précision de filtration de 0,1 micron requise dépasse largement celle des cartouches filtrantes en titane conventionnelles (généralement de 0,22 à 100 microns). Pour y parvenir, nous avons optimisé la distribution granulométrique de la poudre de titane et les paramètres du procédé de frittage. En contrôlant précisément la température et le temps de maintien du frittage, nous avons garanti la performance des cartouches.distribution de la taille des pores plus étroiteetefficacité de séparation supérieure.

Avantages du produit et caractéristiques de performance

Cette série de filtres à noyau en titane personnalisés offre les avantages distincts suivants :

- Précision de filtration exceptionnelle:La filtration de 0,1 micron élimine efficacement les particules minuscules et les micro-organismes des solutions pharmaceutiques, garantissant ainsi la qualité du produit.

- Résistance supérieure à la corrosion:La résistance inhérente à la corrosion du titane permet un fonctionnement dans des environnements difficiles, notamment des acides et des alcalis forts (pH 2-12).

- Résistance aux hautes températures:Résiste à des températures de fonctionnement jusqu'à 280°C (état humide), répondant pleinement aux exigences de l'industrie pharmaceutique en matière de stérilisation à haute température.

- Zéro émission de particules:Conforme aux normes d'hygiène alimentaire et pharmaceutiques GMP, évitant ainsi toute contamination secondaire de la solution d'origine.

- Durée de vie prolongée:Capable de régénération en ligne et de nettoyage facile, offrant une durée de vie nettement plus longue que les cartouches filtrantes à membrane conventionnelles.

Domaines d'application

Cette cartouche filtrante en titane de haute précision trouve de nombreuses applications dans les secteurs suivants :

- Industrie pharmaceutique:Décarbonatation et filtration de précision dans les processus de production de solutions parentérales à grand volume, d'injections à petit volume, de liquides oraux, etc.

- Alimentation et boissons: Filtration de clarification pour boissons, spiritueux, bières, huiles végétales, etc.

- Industrie chimique:Décarbonatation et filtration de précision pour produits liquides et intermédiaires pharmaceutiques.

- Industrie du traitement de l'eau: Filtration de sécurité pour les systèmes d'ultrafiltration, RO et EDI.

Conclusion

Grâce à cette collaboration avec notre client espagnol, Filter Source a une fois de plus démontré son expertise enpersonnalisation de produits de filtration haute performance. De la sélection des matériaux à l'optimisation des processus, et de la personnalisation dimensionnelle à la conception des connexions, nous adhérons systématiquement ànormes élevées et exigences rigoureusespour assurer la livraison de produits et de solutions haut de gamme.

Équipé de technologies avancéesinstallations et procédés de productionLiyuan se consacre depuis des années à la recherche et à la fabrication de consommables pour le traitement de l'eau en tant que fournisseur de solutions environnementales complètes. Nous nous engageons à fournirsolutions de filtration professionnellesà l’échelle mondiale, avec des produits distribués dans les principales villes chinoises et exportés dans le monde entier.

Pour toute demande de filtration spécifique, contactez l'équipe Liyuan dès aujourd'hui. Nous offrons des services experts et personnalisés, adaptés à vos besoins !

Qu’est-ce qu’un filtre en métal fritté ? Guide complet

Filtres en PTFE fritté : filtration avancée pour environnements exigeants

Filtres métalliques frittés : un filtrage de précision pour stimuler la modernisation industrielle

Choix des filtres frittés : aperçu des applications industrielles

Qu'est-ce qu'un disque filtrant en métal fritté ? Guide complet

Que sont les filtres en métal fritté et comment fonctionnent-ils ?

Filtres à poudre frittée

Quelles formes sont disponibles pour les filtres à poudre frittée ?

Les filtres à poudre frittée sont disponibles sous différentes formes, notamment des disques, des tubes, des cartouches filtrantes métalliques, des plaques, des feuilles métalliques poreuses et des coupelles, offrant une polyvalence pour différentes applications.

Filtres en titane fritté

Comment améliorer l’usinabilité des filtres en titane fritté ?

L'usinabilité peut être améliorée en sélectionnant des outils d'usinage à grande vitesse, en créant des environnements de coupe propices et en utilisant des outils de coupe de haute qualité pour optimiser les coûts, la finition de surface et l'intégrité.

Filtre en métal fritté

Qu'est-ce qu'une cartouche filtrante industrielle en métal fritté ?

Une cartouche filtrante industrielle frittée est un composant de filtration fabriqué par un processus de frittage, combinant des poudres métalliques pour créer une structure poreuse. Ces cartouches sont conçues pour des applications industrielles afin d'éliminer les contaminants des liquides et des gaz.

Quels matériaux sont couramment utilisés dans les cartouches filtrantes en métal fritté industriel ?

Les matériaux courants comprennent l’acier inoxydable (304, 316 et 316L), le bronze, l’Inconel, le Monel, le titane et d’autres alliages, en fonction des exigences spécifiques de l’application.

Quels sont les principaux avantages de l’utilisation de cartouches filtrantes en métal fritté industriel ?

Les avantages comprennent une efficacité de filtration élevée, une durabilité, une large résistance aux températures, une compatibilité chimique, des options de personnalisation, des débits élevés, une facilité de nettoyage et une polyvalence dans divers secteurs.

Quel est le processus de nettoyage des cartouches filtrantes industrielles en métal fritté ?

Les méthodes de nettoyage comprennent le lavage à contre-courant, le nettoyage par ultrasons, le nettoyage chimique ou une combinaison de ceux-ci, selon le type de contaminants et le matériau de la cartouche.

Pour l'entreprise

Puis-je visiter votre usine sur place ?

Bien sûr, nous sommes dans le district de Panyu, ville de Guangzhou, province du Guangdong, Chine.

Filtre à mailles en acier inoxydable

Nos filtres à mailles en acier inoxydable offrent une précision de filtration fiable entre 1 μm et 200 μm, offrant une filtration précise et efficace pour une large gamme d'applications.

Filtre à mailles frittées

Nous sommes un pionnier du secteur de la filtration, utilisant des technologies de pointe à l'échelle mondiale pour produire des filtres à mailles frittées performants. Notre filtre à mailles frittées en acier inoxydable est l'un des produits les plus recherchés du marché.

Cartouche filtrante en métal fritté

Nous sommes spécialisés dans la production de cartouches filtrantes industrielles en métal fritté de haute qualité. Fabriquées avec soin à partir de matériaux de première qualité et grâce à des techniques de frittage avancées, ces cartouches garantissent durabilité et performances optimales pour diverses applications industrielles.

Tube en métal fritté

Notre tube en métal fritté est un gage d'excellence dans la filtration industrielle, offrant une solution robuste et efficace pour diverses applications.

© 2024 Tous droits réservés. |Politique de confidentialité•Termes et conditions