Custom Case Study: Sintered Titanium robs for Spanish Clients

Filtration solutions meeting 0.1-micron precision requirements elevate product purity for Spanish pharmaceutical enterprises.

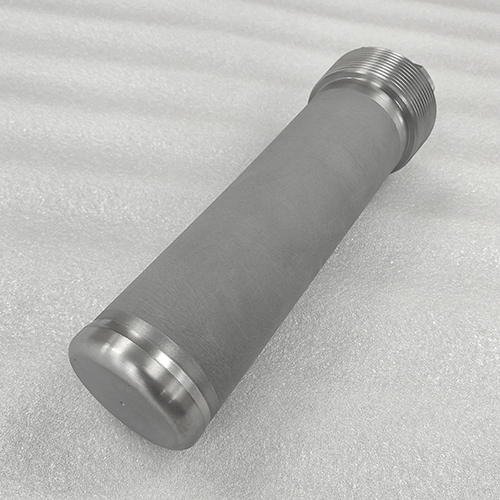

Recently, Guangzhou Liyuan Water Purification Equipment Co., Ltd. successfully completed a custom order for high-performance sintered titanium core filter cartridges for a Spanish client. These specially-specified cartridges (φ75×250mm, 0.1μm filtration precision, 250 units) will be deployed in the client's European pharmaceutical production line.

Project Background and Client Requirements

The Spanish client specializes in high-end pharmaceuticals and requires precision filtration of pharmaceutical solutions during production. Their previously used filter cartridges suffered from insufficient filtration precision and deformation issues, impacting production efficiency and product quality.

The client specified highly detailed technical requirements:

- Cartridge Dimensions: 75mm diameter, 250mm length excluding fittings

- Filtration Precision: 0.1 micron (extremely high precision requirement)

- Connector Configuration: Custom connectors incorporating tension rod structures

- Quantity: 250 units

Notably, the 0.1-micron filtration precision falls within an extremely high-precision range, posing significant challenges to the cartridge manufacturing process.

Solution and Technical Details

Facing this demanding order, Filter Source's technical team responded swiftly, developing a detailed technical solution.

Material Selection and Manufacturing Process

Filter Source utilizes high-purity titanium metal powder (purity ≥99.7%) as raw material, manufactured through advanced powder metallurgy techniques. Titanium filter elements are renowned for their excellent chemical stability, resistance to acid/alkali corrosion, and high-temperature tolerance, making them particularly suitable for the pharmaceutical industry.

The manufacturing process involves sieving, cold isostatic pressing, followed by sintering under high-temperature and high-vacuum conditions. This technique ensures the filter element possesses uniform pore size distribution and stable pore geometry, guaranteeing consistent and reliable filtration performance.

Custom Dimensions and Connection Design

The requested φ75mm diameter represents a non-standard size (standard diameters typically include Ф22mm, Ф30mm, Ф50mm, etc.). Our engineering team custom-designed the mold and manufacturing process according to client specifications, guaranteeing precise dimensional accuracy.

The connection incorporates a tension rod structure, a design that enhances the cartridge's mechanical strength, preventing deformation or damage under pressure fluctuations. The tension rod enables the cartridge to withstand higher pressure differentials (maximum working differential pressure up to 0.6 MPa), extending its service life.

Overcoming the 0.1 Micron Precision Challenge

The 0.1-micron filtration precision requirement far exceeds conventional titanium filter cartridges (typically 0.22-100 microns). To achieve this, we optimized the particle size distribution of titanium powder and sintering process parameters. By precisely controlling sintering temperature and holding time, we ensured the cartridges exhibit narrower pore size distribution and higher separation efficiency.

Product Advantages and Performance Features

This custom titanium core filter series offers the following distinct advantages:

- Exceptional Filtration Precision: 0.1-micron filtration effectively removes minute particulates and microorganisms from pharmaceutical solutions, guaranteeing product quality.

- Superior Corrosion Resistance: Titanium's inherent corrosion resistance enables operation in harsh environments including strong acids and alkalis (pH 2-12).

- High-Temperature Resistance: Withstands operating temperatures up to 280°C (wet state), fully meeting pharmaceutical industry requirements for high-temperature sterilization.

- Zero Particle Shedding: Complies with food hygiene and pharmaceutical GMP standards, preventing secondary contamination of the original solution.

- Extended Service Life: Capable of online regeneration and easy cleaning, offering significantly longer lifespan than conventional membrane filter cartridges.

Application Fields

This high-precision titanium filter cartridge finds extensive application in the following sectors:

- Pharmaceutical Industry: Decarbonation and precision filtration in production processes for large-volume parenteral solutions, small-volume injections, oral liquids, etc.

- Food & Beverage: Clarification filtration for beverages, spirits, beer, vegetable oils, etc.

- Chemical Industry: Decarbonation and precision filtration for liquid products and pharmaceutical intermediates.

- Water Treatment Industry: Security filtration for ultrafiltration, RO, and EDI systems.

Conclusion

Through this collaboration with our Spanish client, Filter Source has once again demonstrated its expertise in customizing high-performance filtration products. From material selection to process optimization, and from dimensional customization to connection design, we consistently adhere to high standards and rigorous requirements to ensure the delivery of premium products and solutions.

Equipped with advanced production facilities and processes, Liyuan has dedicated years to researching and manufacturing water treatment consumables as a comprehensive environmental solutions provider. We are committed to delivering professional filtration solutions globally, with products distributed across major Chinese cities and exported worldwide.

For specialized filtration requirements, contact the Liyuan team today. We offer expert customized services tailored to your needs!

What is Sintered Metal Filter? Complete Guide by Lvyuan

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

Choosing Sintered Filters: An Overview for Industrial Applications

What is a Sintered Metal Filter Disc? A Comprehensive Guide

What Are Sintered Metal Filters and How Do They Work?

Metal mesh filters

Is sintered wire mesh filter reusable?

Yes, sintered wire mesh is reusable. Its robust construction allows for cleaning and regeneration, making it a cost-effective and sustainable choice for filtration applications.

Sintered Metal Filter

What is the cleaning process for industrial sintered metal filter cartridges?

Cleaning methods include backwashing, ultrasonic cleaning, chemical cleaning, or a combination of these, depending on the type of contaminants and the cartridge material.

Sintered Metal Filters

Can sintered metal filters be customized for specific applications?

Yes, sintered metal filters can be customized based on shape, size, material, filtration accuracy, and other specifications to meet the unique requirements of different applications.

Sintered Powder Filters

What materials are commonly used in sintered powder filters?

Common materials include stainless steel (316L, 304L), bronze, Inconel®, Nickel, Monel®, Titanium, and other alloys. The material choice depends on the specific application's requirements.

Stainless Steel Pleated Filter Cartridges

What are the advantages of using Stainless Steel Pleated Filter Cartridges?

Advantages include exceptional durability, high-temperature resistance, corrosion resistance, efficient filtration, versatility in applications, customization options, and cost-effectiveness.

Stainless steel mesh filter

Our stainless steel mesh filters offer dependable filtration accuracy between 1μm and 200μm, delivering precise and efficient filtration for a wide range of applications.

Sintered mesh filter

Lvyuan has been a pioneer in the filtration industry, leveraging global cutting-edge technologies to produce advanced sintered mesh filters. The stainless steel sintered mesh filter stands out as one of the most sought-after products in the market.

Sintered metal tube

Lvyuan's Sintered Metal Tube stands as a hallmark of excellence in industrial filtration, offering a robust and efficient solution for various applications.

Sintered metal filter cartridge

Lvyuan specializes in the production of high-quality industrial-sintered metal filter cartridges. These cartridges are meticulously crafted using advanced sintering techniques and premium materials, ensuring durability and optimal performance in various industrial applications.

© 2024 Lvyuan All Rights Reserved. | Privacy policy • Terms and conditions