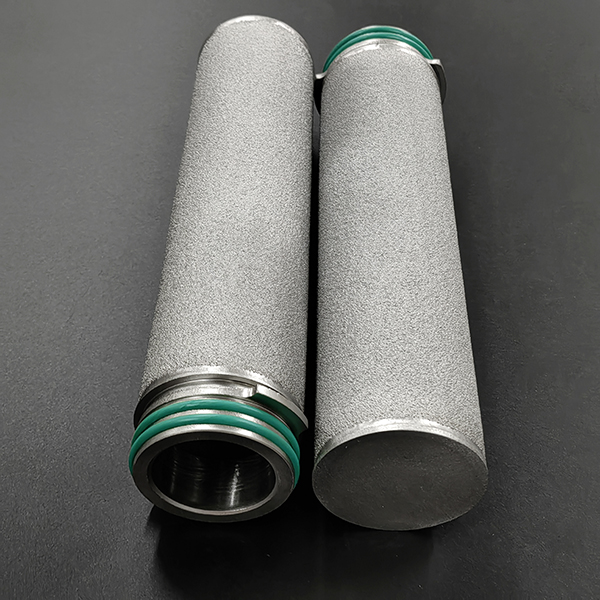

Sintered SS316L powder filter cartridge for Philippine client

Customer background

Industry and demand: A water treatment project in the Philippines requires mass customization of high-precision stainless steel powder filter cartridges due to system upgrades to improve filtration efficiency and extend equipment maintenance cycles.

Application environment: The filter element needs to be adapted to the original component structure to ensure stable sealing, while meeting the requirements of corrosion resistance and pressure resistance for continuous operation.

Solution

- Core product: Customized sintered SS316L powder filter cartridge with a filtration accuracy of 20 µ m and an outer diameter of 60 mm.

- Connector Design: Customize 226 connectors according to the household drawings provided by the customer; The supporting flat sealing structure uses EPDM sealing material to ensure chemical compatibility and high elasticity.

- Structural customization: The total length of the filter element including the end cap is 254 mm; the two locking plates are processed to a thickness of 3.7 mm and a length of 26 mm, enhancing the strength of the buckle and facilitating quick installation and disassembly.

- Quantity scheduling: Supply 100 units at once, assemble them uniformly and pass airtightness and flow testing to ensure batch consistency.

Delivery results

Plug and play: The 226 connector and sealing ring accurately match the customer's equipment, without the need for on-site secondary processing.

Stable Performance: The SS316L sintered structure provides high strength and corrosion resistance, with a precision of 20 µ m meeting the water treatment particle retention standard.

Service Support: Provide installation instructions and maintenance suggestions, and further optimize filter parameters based on operational feedback.

If it needs to be extended to other specifications or supporting systems, we can also continue to assist in customization.

What is Sintered Metal Filter? Complete Guide

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

Choosing Sintered Filters: An Overview for Industrial Applications

What is a Sintered Metal Filter Disc? A Comprehensive Guide

What Are Sintered Metal Filters and How Do They Work?

Stainless Steel Cartridge Filter Housing

What is a stainless steel cartridge filter housing?

The 304 or 316 stainless steel cartridge filter housing is a durable enclosure designed to hold filter cartridges or filter bags for the filtration of liquids or gases in industrial processes.

For company

How can we get the quotation of filter cartridges?

Please tell me the model or specification you need, such as material, length, size, industry, etc.

Stainless Steel Pleated Filter Cartridges

What industries commonly use Stainless Steel Pleated Filter Cartridges?

These cartridges find applications in a range of industries, including petrochemicals, manufacturing, food and beverage, pharmaceuticals, and more, owing to their versatility and efficiency in diverse filtration processes.

Are these pleat cartridges compatible with different filter media?

Yes, Stainless Steel Pleated Filter Cartridges are compatible with various filter media, providing flexibility to adapt to different filtration processes and substances.

Porous Plastic Filter

What are the benefits of using sintered plastic porous filters?

Sintered plastic porous filters offer several advantages, including chemical resistance, high temperature resistance, compatibility with a wide range of fluids, uniform pore size distribution, and excellent filtration efficiency.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

Sintered titanium filter

Discover the efficiency and versatility of our sintered titanium filters, offering an optimal solution for diverse applications, including water treatment, gas diffusion, chemical experiments, and pharmaceutical processes.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions