What are stainless steel filters?

Discover how stainless steel filters seamlessly meet the high-performance filtration needs of the food, pharmaceutical, and oil filtration industries. Manufactured from 304 or 316 stainless steel wire mesh, the filters offer superior resistance to high temperatures and corrosion. Reliable operation under extreme conditions is ensured by stainless steel filters available in three construction types: epoxy-bonded, crimped, and fully welded. Stainless steel filters are durable because they are easy to maintain and reusable, resulting in longer operating life while saving money and reducing environmental impact. Our high-quality stainless steel filters are available for various industrial applications. Please visit Lvyuan's official website for more details about their products.

What is a stainless steel filter?

The stainless steel filter cylinder is constructed from 304 or 316 stainless steel wire mesh, which forms the filter element using different mesh sizes to achieve maximum filtration performance. The choice of filter structures depends on the requirements and includes epoxy-bonded, pressure-welded, and all-welded structures. The stainless steel filter is fully reusable when operators use backwashing, ultrasonic washing, and other non-abrasive cleaning procedures.

What are the different types of filters made of stainless steel?

Based on their structure during the manufacturing process, stainless steel filters can be divided into the following categories:

Epoxy-bonded construction

Epoxy-bonded stainless steel filters can be sold at competitive market prices. The epoxy-bonded element has sufficient strength to operate under high-pressure conditions, making it suitable for a wide range of fluids.

Crimped construction

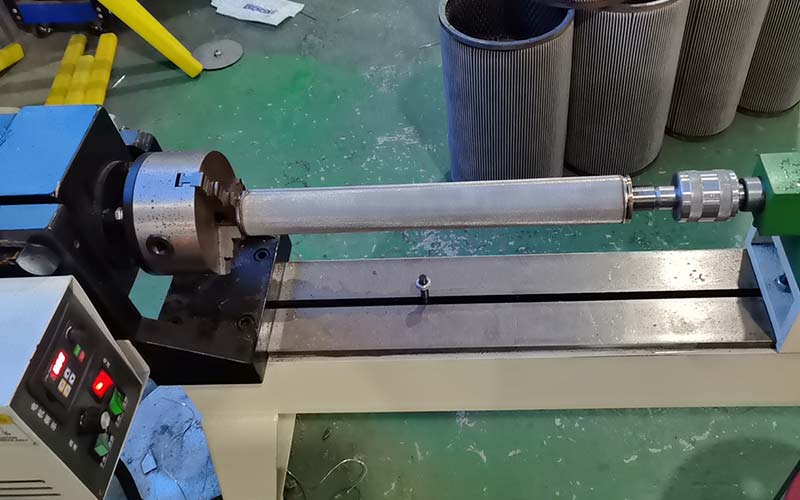

The industrial process requires this material to clarify and filter fluids for its filter core applications. The system is effective for batch processing applications. The filter elements are available in pleated or columnar (covered) forms with lightweight cores and support rings inside. The industrial process filter element is made of stainless steel and is joined by crimping and welding. The process avoids brazing or epoxy bonding methods because of the temperature and compatibility issues associated with cellulose and synthetic cellulose filter elements.

All-welded construction

All components of the metal mesh filter element use stainless steel assemblies, including end caps, center tubes, and metal mesh. The element remains easy to service during hazardous fluid filtration operations, reducing operating costs.

The metal mesh element demonstrates excellent performance in extreme environments due to its fully welded construction. The element is suitable for use in both high-pressure and corrosive fluid conditions. This system eliminates the side effects of media migration while providing precise filtration of particles larger than microns. The element will return to service after cleaning by backwash or alternative cleaning methods.

This filtration solution is well suited to high-pressure applications due to its durable welded construction. Our company supplies elements tested for collapse pressure rating. The woven wire mesh filter element is an excellent solution for applications involving extremely high temperatures that would damage traditional epoxy structural elements.

The welded mesh elements are annealed to prevent failure due to intergranular corrosion combined with high-pressure effects.

How does a stainless steel filter work?

Stainless steel filters use fine mesh in combination with perforated metal to trap particles while releasing liquids and gases during filtration. Their corrosion-resistant materials make them suitable for industries such as food processing, pharmaceuticals, and oil filtration. The filtration design determines which contaminants of different sizes are trapped while both liquids and gases continue to flow. Multiple filtration layers, backflushing, and cleaning systems are used in different types of filters to enhance their performance. Stainless steel filters are a valuable investment as they can withstand high temperatures and provide a long service life while reducing costs and protecting the environment.

What are the advantages of stainless steel filters?

Can withstand high voltage

The filter element operates under high-pressure resistance conditions. High-pressure fluid filtration uses this element to extend the life of equipment in high-pressure pipelines.

Can withstand extremely high temperatures

The stainless steel material shows exceptional durability when exposed to high temperatures. The stainless steel filter core is stable in high-temperature conditions where other materials tend to deform.

Easy to clean and reuse

Stainless steel is easy to clean and reusable. The cleaning process requires effort to remove contaminants before reassembling the instrument for the next operation. The stainless steel filter core can be washed several times to ensure complete removal of any particles that might contaminate its surface.

Long service life

Increased filtration area through the use of pleated stainless steel core technology. This extends the filter replacement cycle and increases filter life. The element is corrosion-resistant during secondary fluid flow.

What are the applications for stainless steel filters?

Stainless steel filters exist for demanding applications in harsh environments that require durable, solid filtration materials. The filters maintain reliable functionality under harsh operating conditions, which include both high pressure differentials and extreme temperatures. These filters serve as excellent liquid filters for applications requiring special material compatibility, protecting against contamination while maintaining process integrity. Stainless steel filters have a wide range of industrial applications in the chemical processing, oil and gas, pharmaceutical, food and beverage, and water treatment industries because they offer both high performance and durability.

Conclusion

Strong structural material is a fundamental requirement when operating in harsh conditions. Protecting your system requires structural materials regardless of the severe operating conditions your applications face, including high operating pressures and pressure differentials, extreme temperatures, and fluid compatibility requirements. The material advantages of stainless steel filter elements allow designers to customize products according to specifications for material choice and strength level, flow rate and thickness, micron grade, and environmental conditions.

As an elite in the industry, we are also committed to the research and production of related products and will do our best to provide customers with high-quality products and services.

If you are interested in a stainless steel filter, you can click on the official website of Lvyuan for more information.

What is Sintered Metal Filter? Complete Guide

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

Choosing Sintered Filters: An Overview for Industrial Applications

What is a Sintered Metal Filter Disc? A Comprehensive Guide

What Are Sintered Metal Filters and How Do They Work?

For products

How can I request a quote or get more information about your sintered metal filters?

For inquiries, quotes, or additional information about our sintered metal filters, please contact our sales team through our website or by reaching out to [contact information]. We are happy to assist you with any questions or requirements you may have.

Sintered Powder Filters

What is a sintered powder filter?

A sintered powder filter is a porous filtration medium created by compacting and sintering metal powders. It is designed to provide efficient and precise filtration in various industrial applications.

What are the key advantages of sintered powder filters?

Sintered powder filters offer high filtration efficiency, durability, resistance to temperature and corrosion, and customization options in terms of shape, pore size, and material.

Sintered Metal Filters

Can sintered metal filters be cleaned and reused?

Yes, sintered metal filters are designed to be cleaned and reused. Their durability and resistance to fouling make them suitable for applications where filter cleaning is necessary.

Porous Plastic Filter

How do I clean and maintain sintered porous filter discs?

Cleaning methods depend on the material used. For metal discs, methods may include backwashing, ultrasonic cleaning, or chemical cleaning. Polyethylene discs are often cleaned with mild detergents. Regular maintenance ensures a prolonged operational life.

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions