Delivering PTFE Sintered Filter Cartridges in Malaysia

We successfully delivered PTFE sintered filter cartridges to a major client in Malaysia, enhancing their filtration capabilities. Our high-quality cartridges are designed to meet industry standards, ensuring optimal performance and durability. Discover how PTFE sintered filter cartridges can elevate your operations with unmatched efficiency and reliability.

Introduction

In November 2024, our team successfully completed an order for a Malaysia-based client seeking a filtration solution for their chemical processing plant. The client required 300 units of PTFE sintered filter cartridges, tailored to specific operational and environmental needs. Here's how we delivered a customized solution that met their expectations.

Customer Requirements

The client needed a high-quality filter cartridge with the following specifications:

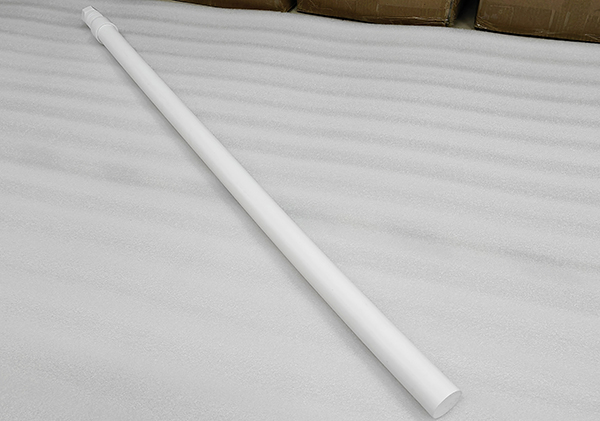

Product Name: PTFE Sintered Filter Cartridge

Size: 38 × 20 × 1000 mm

Filtration Accuracy: 0.2 µm

Connector Type: Full PTFE M22 connector

Quantity: 300 units

The filters were intended for use in a corrosive chemical environment, requiring exceptional chemical resistance, durability, and precise filtration performance.

Challenges and Customization

·Material Compatibility:

PTFE was chosen for its outstanding resistance to harsh chemicals, high temperatures, and hydrophobic properties, ensuring long-term reliability in a demanding environment.

·Precision Manufacturing:

The required filtration accuracy of 0.2 µm posed a challenge, demanding meticulous sintering processes to achieve uniform porosity and consistent performance.

·Custom Connector Design:

The M22 connector needed to be fabricated entirely from PTFE to ensure compatibility with the client's chemical systems. Our team designed and manufactured these connectors with tight tolerances to ensure a secure fit and leak-free operation.

Production and Delivery

The order was completed within 4 weeks, meeting the client’s tight timeline without compromising on quality. The production process involved:

· Advanced sintering technology to achieve the specified dimensions and filtration accuracy.

·Rigorous quality control, including pore size analysis and chemical resistance testing, to verify product performance.

·Secure packaging to prevent damage during transportation to Malaysia.

Customer Feedback

The client was highly satisfied with the delivered products, particularly praising:

Precision and Quality: The filters met all performance requirements, including chemical resistance and filtration efficiency.

On-Time Delivery: Despite the customization, the order was shipped promptly.

Technical Support: Our team provided comprehensive guidance on installation and maintenance, ensuring smooth integration into their system.

Conclusion

This project underscores our expertise in delivering custom filtration solutions for specialized industrial applications. If you need high-performance PTFE sintered filter cartridges or other tailored filtration products, our team is here to assist.

FAQs

1.What industries commonly use PTFE sintered filter cartridges?

PTFE filters are widely used in chemical processing, pharmaceuticals, food and beverage, and electronics due to their chemical resistance and precision filtration.

2.What is the advantage of PTFE over other materials?

PTFE offers exceptional resistance to harsh chemicals, high temperatures, and hydrophobicity, making it ideal for demanding environments.

3.Can the dimensions of the filter cartridges be customized?

Yes, we can customize dimensions, filtration accuracy, and connector types to meet specific requirements.

4.How long does it take to manufacture a custom filter order?

Production timelines depend on order complexity but typically range from 3 to 6 weeks.

5.Do you provide installation support for international customers?

We provide detailed installation guides and remote technical assistance for all our products.

Need a customized filtration solution? Contact us today for a tailored consultation!

What is Sintered Metal Filter? Complete Guide

Sintered PTFE Filters: Advanced Filtration for Demanding Environments

Metal Sintered Filters: Precision Filtering to Drive Industrial Upgrading

Choosing Sintered Filters: An Overview for Industrial Applications

What is a Sintered Metal Filter Disc? A Comprehensive Guide

What Are Sintered Metal Filters and How Do They Work?

Sintered Metal Filter

What is an industrial sintered metal filter cartridge?

An industrial sintered filter cartridge is a filtration component made through a sintering process, combining metal powders to create a porous structure. These cartridges are designed for industrial applications to remove contaminants from liquids and gases.

What materials are commonly used in industrial-sintered metal filter cartridges?

Common materials include stainless steel (304, 316, and 316L), bronze, Inconel, Monel, titanium, and other alloys, depending on the specific requirements of the application.

What are the key advantages of using industrial-sintered metal filter cartridges?

Advantages include high filtration efficiency, durability, wide temperature resistance, chemical compatibility, customization options, high flow rates, ease of cleaning, and versatility across various industries.

Metal mesh filters

Can sintered wire mesh filter be used in high-pressure applications?

Yes, sintered wire mesh is suitable for high-pressure applications due to its high strength and durable structure. However, specific pressure ratings may vary based on the material and design, so it's essential to consider these factors.

What maintenance is required for sintered wire mesh filter?

Regular cleaning is the primary maintenance for sintered wire mesh. The cleaning frequency depends on the application and the type of contaminants being filtered. Follow the manufacturer's guidelines for proper maintenance.

Stainless Steel Pleated Filter Cartridges

What are the main applications of Stainless Steel Pleated Filter Cartridges?

These cartridges are commonly used for polymer melt filtration, high-temperature gas and steam filtration, and filtration of high-temperature liquids and viscous fluids in industries such as petrochemicals, manufacturing, and more.

For products

Are your sintered metal filters compliant with industry standards?

Yes, our sintered metal filters conform to industry standards, and we ensure compliance with quality management systems such as ISO9001. This commitment reflects our dedication to delivering high-quality filtration solutions.

Bag filter housing

Bag filter housings are essential components in industrial filtration systems, designed to remove contaminants from liquids. To enhance the functionality and efficiency of bag filter housings, various features can be incorporated.

Sintered powder metal filters

Sintered powder metal filters are crafted from compressed and sintered metal powders, forming a porous structure. Porosity: 28%-50% Permeability: 0.02-20L/cm²minPa Pressure Resistance: 0.5Mpa Temperature Resistance: Less than 280℃

Stainless steel multi cartridge filter housing

Discover unparalleled filtration efficiency with our Stainless Steel Multi Cartridge Filter Housing – a testament to precision engineering and reliability.

Sintered wire mesh filter

Benefit from outstanding high-pressure resistance and consistent filtration efficiency with our sintered metal mesh. Our sintered wire mesh finds versatile applications in diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer processing, petrochemical industries, hydraulic filters, and more.

Sanitary filter housing

This filter housing will allow you to filter large volumes of nanoemulsion with ease. Sanitary vent and drain valves permit easy venting, draining, sampling, or integrity testing operations. The new cartridge locking design features additional cut-outs for traditional half-moon portions of the Code 7 bayonet locks, enhancing clean ability and drain ability.

stainless steel filter water

Our sintered stainless steel filter stands as a pivotal filtration element crafted through a meticulous sintering process, with stainless steel serving as the core material.

Stainless Steel Duplex filter housing

As the manufacturer, we offer a comprehensive range of Duplex Filter Housings designed to provide efficient and reliable filtration solutions for various industrial applications.

Stainless steel pleated filter cartridge

Our Stainless Steel Pleat Filter Cartridge constructed from high-quality SS 304 or SS 316L material, this filter exhibits exceptional resistance to high temperatures and rust.

© 2024 All Rights Reserved. | Privacy policy • Terms and conditions